Introduction: The Wheel Reinvented

For over a century, the basic layout of automobiles has remained largely unchanged: an engine at the front, a trunk at the back, and passengers sandwiched in between. But what if we could reimagine vehicles from the ground up, optimizing for both efficiency and passenger space? Enter hub motors, also known as in-wheel motors, a technology that's poised to revolutionize electric vehicle design and performance.

Hub motors represent a paradigm shift in how we approach vehicle propulsion. By integrating electric motors directly into the wheels, they offer a host of benefits that could reshape the automotive landscape. This article delves deep into the world of hub motors, exploring their technology, advantages, challenges, and potential to drive the future of electric mobility.

Understanding Hub Motors: Power at the Periphery

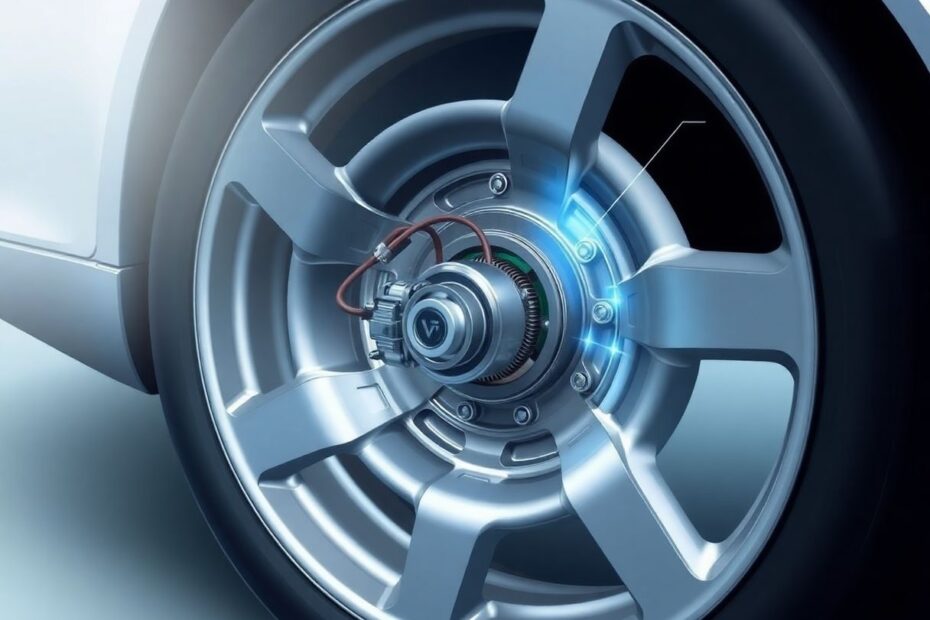

At its core, a hub motor is an electric motor built directly into the wheel hub of a vehicle. This seemingly simple concept carries profound implications for vehicle design and performance. Unlike conventional drivetrains, where a centralized motor powers the wheels through a complex system of gears and shafts, hub motors provide independent, direct drive to each wheel.

To truly appreciate the innovation of hub motors, it's essential to understand their inner workings. Most hub motors utilize brushless DC (BLDC) motor technology, a sophisticated system that offers high efficiency and precise control. Inside a BLDC hub motor, you'll find a set of stationary electromagnetic coils (typically 6 or more) surrounded by a ring of permanent magnets. This configuration is often the reverse of traditional electric motors, where the inner rotor spins within a static outer stator.

The magic happens through electronic commutation. As electrical current flows through the coils in a carefully choreographed sequence, it creates a rotating magnetic field. This field interacts with the permanent magnets, causing the wheel to spin. Hall-effect sensors detect the rotor's position, allowing for precise control of the motor's speed and torque.

This setup eliminates the need for mechanical brushes, reducing friction and wear while increasing efficiency, especially at lower speeds. The result is a compact, powerful propulsion system integrated seamlessly into the vehicle's wheels.

The Advantages of Hub Motors: A Wheel of Benefits

The adoption of hub motors in electric vehicles brings a multitude of advantages that extend far beyond mere propulsion. Let's explore these benefits in detail:

Simplified Vehicle Design

By eliminating the need for a traditional drivetrain, hub motors open up new possibilities in vehicle architecture. Without a bulky engine compartment or transmission tunnel, designers have unprecedented freedom to reimagine the vehicle's interior and exterior. This could lead to more aerodynamic shapes, increased passenger space, and innovative storage solutions.

Improved Weight Distribution and Handling

Placing motors directly in the wheels can significantly enhance a vehicle's weight balance and lower its center of gravity. This improved weight distribution contributes to better handling, stability, and overall driving dynamics. The reduced polar moment of inertia can make the vehicle more responsive to steering inputs, potentially enhancing both safety and driving pleasure.

Precise Traction Control and Torque Vectoring

With independent control over each wheel, hub motors enable advanced traction control and torque vectoring systems. This level of control allows for instantaneous adjustments to power delivery at each wheel, improving grip in challenging conditions and enhancing cornering performance. In effect, every hub motor-equipped vehicle has the potential for sophisticated all-wheel drive capabilities without the mechanical complexity traditionally associated with such systems.

Enhanced Energy Efficiency

Hub motors can be more energy-efficient than centralized motor systems due to the elimination of power transmission losses through gears and driveshafts. Additionally, their ability to provide regenerative braking at each wheel maximizes energy recovery during deceleration, further improving overall efficiency.

Modular Design and Maintenance

The modular nature of hub motors simplifies both manufacturing and maintenance. In theory, repairs or upgrades could be performed on individual wheels rather than requiring work on the entire drivetrain. This modularity could lead to more cost-effective maintenance and potentially longer vehicle lifespans.

Overcoming Challenges: Engineering Solutions

While the advantages of hub motors are compelling, their implementation is not without challenges. Engineers and researchers are actively working to address these issues:

Unsprung Mass: A Weighty Concern

One of the primary concerns with hub motors is the increase in unsprung mass – the weight of the vehicle components not supported by the suspension. Additional weight in the wheels can negatively impact ride quality and handling. However, innovative solutions are emerging:

- Advanced suspension systems specifically designed to counteract the effects of increased unsprung mass.

- Development of lighter motor designs using high-strength, low-density materials.

- Integration of active suspension technologies to dynamically adjust to road conditions.

Durability in Harsh Environments

Exposed to the elements and road debris, hub motors must be exceptionally durable. Engineers are developing robust enclosures and sealing technologies to protect the motors from water, dust, and impacts. Additionally, advanced cooling systems are being integrated to manage the heat generated during operation, ensuring longevity and consistent performance.

Balancing Torque and Speed

Direct-drive hub motors can struggle to provide both high torque for acceleration and high speed for cruising without a gearbox. Researchers are exploring multi-speed hub motor designs and advanced control algorithms to optimize performance across a wide range of operating conditions.

Cost Considerations

Manufacturing complex, high-power motors for each wheel can be more expensive than producing a single central motor. However, as production scales up and designs are refined, costs are expected to decrease. The potential savings in other areas of vehicle design and manufacturing may also offset the initial higher cost of hub motors.

Real-World Applications: Hub Motors in Action

Hub motors are already finding their way into various electric vehicles, demonstrating their versatility and potential:

Electric Bicycles and Personal Mobility Devices

E-bikes, electric scooters, and skateboards often utilize hub motors for their compact size and ease of integration. These applications showcase the technology's scalability and efficiency in small, lightweight vehicles.

Urban Electric Cars

Compact city cars are ideal candidates for hub motor technology. Vehicles like the Protean Electric's demonstration car, based on a Volkswagen Golf platform, have shown how hub motors can significantly increase interior space while maintaining or improving performance.

Heavy-Duty Vehicles

Surprisingly, hub motors are also being explored for use in larger vehicles. Companies like Equipmake are developing high-power hub motors for electric buses, leveraging the technology's advantages in torque delivery and space efficiency.

Concept Vehicles and Future Designs

Many futuristic car designs incorporate hub motors to showcase new possibilities in vehicle layout. Concept cars like the Nissan BladeGlider and EDAG Light Cocoon demonstrate how hub motors can enable radical new vehicle architectures.

The Future of Hub Motors: Innovation on the Horizon

As technology continues to advance, we can expect to see further innovations in hub motor design and application:

Higher Efficiency and Power Density

Ongoing research into novel materials and motor topologies promises to increase the efficiency and power density of hub motors. Developments in nanotechnology and advanced manufacturing techniques could lead to motors that are lighter, more powerful, and more efficient than current designs.

Integrated Systems

Future hub motors may combine propulsion with advanced suspension, braking, and steering systems all within the wheel assembly. This level of integration could further simplify vehicle design and improve overall performance.

Smart Wheels

The incorporation of sensors and artificial intelligence into hub motor systems could enable real-time adaptation to road conditions, driver behavior, and vehicle dynamics. These "smart wheels" could optimize performance, efficiency, and safety on the fly.

Wireless Power Transfer

Research into inductive charging technology could eventually lead to hub motors that can charge while driving over specially equipped roads. This development could address range anxiety and potentially reduce the size and weight of onboard batteries.

Conclusion: A Revolution in Motion

Hub motors represent more than just a new way to power vehicles; they embody a fundamental rethinking of automotive design and engineering. By moving the motor directly into the wheel, we open up new possibilities for vehicle efficiency, performance, and design flexibility.

As we look to the future of transportation, hub motors are poised to play a crucial role in creating more efficient, spacious, and versatile electric vehicles. From compact urban runabouts to long-range electric trucks, the potential applications of hub motor technology are vast and exciting.

The challenges that remain – such as managing unsprung mass and ensuring durability – are being actively addressed by researchers and engineers around the world. As solutions emerge and the technology matures, we can expect to see hub motors becoming an increasingly common feature in electric vehicles.

The revolution in electric vehicle design is not just under the hood – it's in the wheels themselves. Hub motors are turning the concept of vehicle propulsion on its head, promising a future where electric vehicles are not just cleaner, but fundamentally better in design and performance. As this technology continues to evolve, it may well drive us into a new era of automotive innovation, where the limitations of traditional vehicle design are left in the rearview mirror.