Introduction: The Unsung Hero of Combustion

In the world of internal combustion engines, few components are as fascinating and fundamental as the carburetor. This ingenious device, which has powered vehicles for over a century, is a masterpiece of mechanical engineering. At its core, a carburetor performs a seemingly simple task: mixing air and fuel in the perfect proportions to keep an engine running smoothly, efficiently, and powerfully. Yet, the elegance of its design and the complexity of its operation make it a subject worthy of deep exploration.

Imagine standing at the helm of a grand orchestra, tasked with blending various instruments to create a harmonious symphony. This is essentially what a carburetor does, but instead of musical notes, it's juggling air molecules and fuel droplets. The result, when done correctly, is the sweet hum of a well-tuned engine, ready to propel you down the road.

In this comprehensive exploration, we'll delve into the intricate workings of carburetors, unraveling their mysteries and appreciating their crucial role in the history and ongoing evolution of engine technology.

The Fundamentals: The Recipe for Combustion

Before we dive into the specifics of carburetor operation, it's essential to understand the basic principle that drives all internal combustion engines:

Fuel + Air + Spark = Combustion

This simple equation is the foundation upon which all gasoline engines operate. However, like any good recipe, the proportions are critical. The ideal air-fuel ratio for gasoline engines, known as the stoichiometric ratio, is approximately 14.7 parts air to 1 part fuel by weight. This ratio ensures complete combustion, maximizing power output while minimizing harmful emissions.

However, engines often require slight deviations from this ideal ratio depending on operating conditions. For instance, during cold starts, a richer mixture (more fuel relative to air) is needed to ensure proper ignition. Conversely, during high-load conditions, a slightly leaner mixture can help prevent engine knock and improve efficiency.

The carburetor's primary job is to maintain this delicate balance across a wide range of engine speeds and load conditions. It's a task that requires precision, adaptability, and a dash of mechanical wizardry.

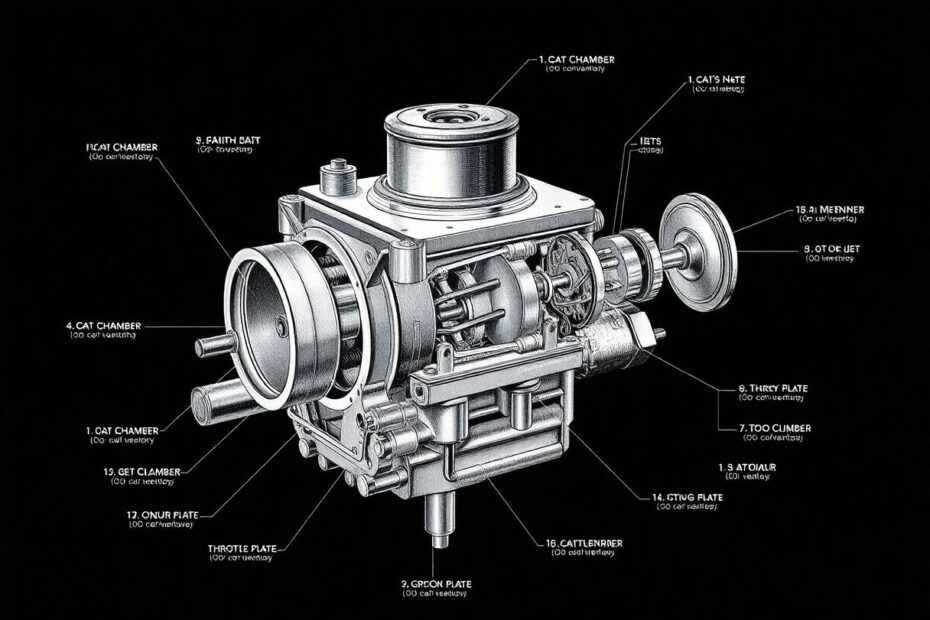

The Anatomy of a Carburetor: A Tour of Its Components

To truly appreciate how a carburetor works, we need to understand its key components. Let's take a guided tour through the anatomy of this remarkable device:

The Venturi: The Heart of the Carburetor

At the core of every carburetor is the venturi, a narrow section in the air passage that operates on a principle first described by Italian physicist Giovanni Battista Venturi in the 18th century. As air flows through this constricted area, its velocity increases and its pressure decreases, creating a vacuum effect. This low-pressure zone is key to drawing fuel into the airstream.

The venturi's design is a delicate balance. Too narrow, and it restricts airflow excessively, limiting engine power. Too wide, and the vacuum effect is insufficient to draw in the right amount of fuel. Carburetor designers must carefully calculate the optimal venturi size for each specific engine application.

The Float Chamber: Fuel Supply Management

Adjacent to the main body of the carburetor is the float chamber, a reservoir that maintains a constant supply of fuel. The float chamber houses two critical components:

- The float: A buoyant device that rises and falls with the fuel level.

- The needle valve: Controlled by the float, this valve regulates fuel flow into the chamber.

As fuel is consumed, the float drops, opening the needle valve and allowing more fuel to enter the chamber. When the chamber is full, the float rises, closing the valve and stopping the fuel flow. This simple yet effective mechanism ensures a consistent fuel supply, crucial for maintaining the proper air-fuel ratio.

Jets and Circuits: Fine-Tuning the Mixture

Modern carburetors feature an array of jets and circuits, each designed to optimize the air-fuel mixture for specific operating conditions:

- Main Jet: Controls fuel flow during normal driving conditions.

- Idle Jet: Provides the correct mixture when the engine is idling.

- Accelerator Pump: Delivers an extra shot of fuel when the throttle is suddenly opened, preventing hesitation.

- Power Valve: Enriches the mixture during high-load conditions to prevent detonation and ensure maximum power output.

These components work in concert to ensure the engine receives the optimal air-fuel mixture across its entire operating range.

The Throttle Plate: Controlling Airflow

The throttle plate is a pivoting valve that controls how much of the air-fuel mixture enters the engine. Connected to the accelerator pedal, it opens as you press down, allowing more mixture into the engine and increasing power output. The throttle plate's position is crucial in determining engine speed and power output.

The Physics of Fuel Delivery: The Venturi Effect in Action

The venturi effect, the key principle behind carburetor operation, is a fascinating application of fluid dynamics. As air passes through the narrowed venturi section, several things happen:

- The air velocity increases due to the constriction.

- According to Bernoulli's principle, this increase in velocity results in a decrease in pressure.

- The low-pressure area creates a vacuum effect.

- This vacuum draws fuel from the float chamber through the main jet into the airstream.

The beauty of this system lies in its self-regulating nature. As engine speed increases and more air flows through the carburetor, the stronger vacuum effect automatically draws in more fuel, maintaining the proper air-fuel ratio.

To put some numbers to this effect, consider that in a typical automotive carburetor, the pressure drop in the venturi can be as much as 5 kPa (0.72 psi) below atmospheric pressure. This seemingly small pressure difference is sufficient to draw fuel from the float chamber and atomize it into a fine mist, ready for combustion.

Carburetor Tuning: The Art of Perfecting Performance

One of the most intriguing aspects of carburetors is their tunability. Enthusiasts and mechanics can adjust various components to optimize engine performance for specific applications or conditions. This process, known as carburetor tuning, is both an art and a science.

Key aspects of carburetor tuning include:

- Jet Sizing: Changing the size of the main and idle jets affects the amount of fuel delivered at different engine speeds.

- Float Level Adjustment: Altering the float level in the float chamber affects the overall richness of the mixture.

- Accelerator Pump Adjustment: Fine-tuning the accelerator pump can improve throttle response and eliminate hesitation.

- Mixture Screw Adjustment: This allows for minor adjustments to the idle mixture, affecting low-speed operation.

Proper tuning requires a deep understanding of engine dynamics and often involves iterative testing and adjustment. Many enthusiasts find this process rewarding, as it allows for a direct connection with the engine's operation and performance.

The Legacy of Carburetors in the Age of Fuel Injection

While electronic fuel injection (EFI) has largely replaced carburetors in modern automobiles due to its precision and adaptability, carburetors continue to play a significant role in various applications:

Small Engines

Lawnmowers, chainsaws, and many other small engines still rely on carburetors due to their simplicity and cost-effectiveness. In these applications, the carburetor's mechanical nature and ease of maintenance make it an ideal choice.

Classic and Vintage Vehicles

Many classic car enthusiasts prefer to maintain original carburetor setups for authenticity and the unique driving experience they provide. The distinctive sound and feel of a carbureted engine are part of the charm for many vintage vehicle aficionados.

Certain Racing Classes

Some racing categories, particularly in motorsports with a focus on tradition or cost control, still mandate the use of carburetors. In these applications, high-performance carburetors can be finely tuned to extract maximum power from an engine.

Educational Value

Understanding carburetor operation provides a solid foundation for grasping more complex fuel systems. Many automotive and engineering programs still include carburetor study as part of their curriculum, recognizing its value in teaching fundamental principles of engine operation.

The Future of Fuel Mixing: Lessons from Carburetor Design

While carburetors may seem like relics of the past in the age of direct fuel injection and hybrid powertrains, the principles behind their operation continue to influence modern engine design. The quest for the perfect air-fuel mixture remains a central challenge in internal combustion engine development.

Advanced fuel injection systems, while more precise and adaptable than carburetors, still aim to achieve the same goal: delivering the right amount of fuel at the right time for optimal combustion. The lessons learned from decades of carburetor development and tuning inform the algorithms and control strategies used in modern engine management systems.

Moreover, as the automotive industry explores alternative fuels and novel combustion strategies, the fundamental understanding of air-fuel mixing that carburetors exemplify remains relevant. Whether it's optimizing gasoline direct injection spray patterns or developing new ways to mix hydrogen in fuel cell vehicles, the spirit of the carburetor lives on in the continuing pursuit of efficient, powerful, and clean engines.

Conclusion: Appreciating the Carburetor's Ingenious Simplicity

As we've explored the intricate workings of carburetors, it's clear that these devices are marvels of mechanical engineering. From the elegant application of the venturi effect to draw in fuel, to the self-regulating nature of their design, carburetors represent a pinnacle of pre-electronic engine technology.

While they may lack the precision and adaptability of modern fuel injection systems, carburetors possess a charm and simplicity that continues to captivate enthusiasts and engineers alike. Their ability to maintain proper air-fuel mixtures across a wide range of operating conditions, using purely mechanical means, is a testament to human ingenuity.

As we move towards an automotive future dominated by electronics and alternative powertrains, it's worth taking a moment to appreciate the carburetor. This device, which for over a century kept our engines running smoothly, efficiently, and powerfully, holds valuable lessons for engineers and enthusiasts alike. Its legacy lives on in the principles that continue to shape modern fuel delivery systems and in the hearts of those who appreciate the art and science of internal combustion engines.

Understanding carburetors not only provides insight into automotive history but also offers a deeper appreciation for the ongoing challenges in engine design. As we face the future of transportation, the humble carburetor reminds us that sometimes, elegant mechanical solutions can solve complex problems, a lesson that remains relevant in our increasingly digital world.