In the realm of automotive engineering, few components have had as profound an impact on environmental protection as the catalytic converter. This unassuming device, tucked away in the exhaust system of modern vehicles, plays a crucial role in reducing harmful emissions and improving air quality worldwide. As we delve into the inner workings of catalytic converters, we'll explore their history, function, and importance in the ongoing battle against pollution.

The Origins of a Pollution-Fighting Marvel

The story of the catalytic converter begins in the mid-20th century, as concerns about air pollution from vehicles began to mount. In 1950, French mechanical engineer Eugene Houdry, who had previously made significant contributions to the petroleum industry, patented the first catalytic converter design. Houdry's invention was initially intended to reduce smog-forming emissions from factory smokestacks, but he quickly recognized its potential for automotive applications.

However, it wasn't until the 1970s that catalytic converters began to see widespread adoption in vehicles. The catalyst for this change was the U.S. Clean Air Act of 1970, which set stringent new standards for vehicle emissions. Automakers, faced with the need to drastically reduce pollutants from their vehicles, turned to catalytic converter technology as a solution.

In 1975, the first production vehicles equipped with catalytic converters rolled off assembly lines. These early models were two-way converters, capable of addressing carbon monoxide (CO) and hydrocarbon (HC) emissions. By 1981, three-way catalytic converters had become the standard, adding the ability to reduce nitrogen oxides (NOx) to their repertoire of pollution-fighting capabilities.

The Science Behind the Solution

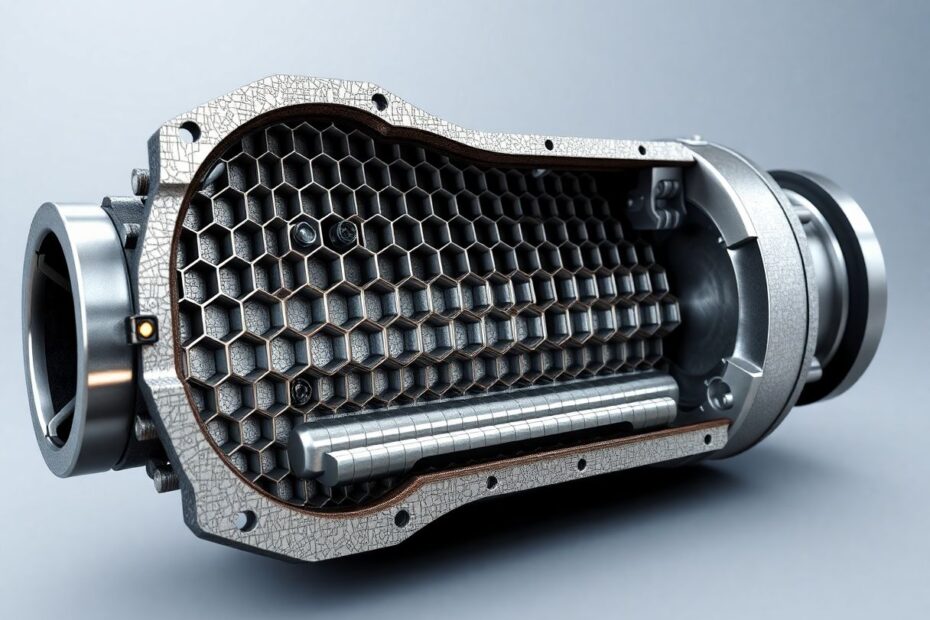

At its core, a catalytic converter is a remarkable feat of chemical engineering. The device consists of a honeycomb-like structure made of ceramic or metal, coated with precious metals such as platinum, palladium, and rhodium. These metals serve as catalysts, facilitating chemical reactions that transform harmful pollutants into less noxious substances.

The three primary reactions that occur within a modern three-way catalytic converter are:

- Reduction of nitrogen oxides (NOx) to nitrogen (N2) and oxygen (O2)

- Oxidation of carbon monoxide (CO) to carbon dioxide (CO2)

- Oxidation of unburned hydrocarbons (HC) to carbon dioxide (CO2) and water (H2O)

These reactions occur simultaneously as exhaust gases pass through the converter, effectively treating multiple pollutants in a single process. The efficiency of these reactions is remarkable, with modern catalytic converters capable of eliminating up to 90% of harmful emissions when operating at peak performance.

It's worth noting that the catalytic process requires high temperatures to function effectively, typically above 300°C (572°F). This means that during the first few minutes of operation, when the engine and exhaust system are still cold, emissions can be higher. To address this issue, some modern vehicles employ electrically heated catalysts or position the converter closer to the engine to reduce warm-up time.

The Catalyst Conundrum: Precious Metals and Environmental Trade-offs

While catalytic converters have undoubtedly improved air quality in urban areas worldwide, their reliance on precious metals presents some environmental and economic challenges. Platinum, palladium, and rhodium – the primary catalytic materials used in converters – are rare and expensive resources. Their extraction and processing can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

According to the International Platinum Group Metals Association, a typical catalytic converter contains about 3-7 grams of platinum group metals. With millions of vehicles produced each year, the demand for these metals is substantial. In 2020, approximately 39% of global platinum demand and 80% of palladium demand was for automotive catalysts.

This reliance on precious metals has made catalytic converters a target for theft, particularly when metal prices are high. The National Insurance Crime Bureau reported a significant increase in catalytic converter thefts in recent years, with over 14,000 reported thefts in the U.S. in 2020 alone.

Researchers are actively working on developing new catalyst materials that could reduce or eliminate the need for precious metals. Promising avenues include nanotechnology-based catalysts and alternative materials such as perovskites, which have shown potential for high catalytic activity at lower costs.

Diesel Dilemmas: Adapting Catalytic Technology

While our discussion has primarily focused on gasoline engines, diesel engines present unique challenges in emissions control. Diesel catalytic converters differ from their gasoline counterparts in several ways:

Oxidation focus: Diesel catalytic converters primarily perform oxidation reactions, converting CO and HC to CO2 and H2O. They are less effective at reducing NOx emissions.

Additional systems: To address NOx emissions, many diesel vehicles employ additional technologies such as Selective Catalytic Reduction (SCR) systems, which use a urea-based solution (often called AdBlue) to convert NOx into nitrogen and water.

Particulate matter: Diesel engines produce significant amounts of particulate matter (soot), which is not effectively addressed by traditional catalytic converters. To combat this, many diesel vehicles use Diesel Particulate Filters (DPF) in conjunction with catalytic converters.

The challenges of diesel emissions have come under increased scrutiny in recent years, particularly following the Volkswagen emissions scandal of 2015. This event highlighted the complexities of real-world emissions testing and the potential for discrepancies between laboratory results and actual on-road performance.

Beyond Traditional Catalysts: Innovations in Emissions Control

As vehicle technology evolves, so too does the field of emissions control. Several innovative approaches are being developed to complement or potentially replace traditional catalytic converters:

Plasma-assisted catalysis: This technology uses electrical discharges to create a plasma state within the exhaust system, enhancing the catalytic reactions and potentially reducing the amount of precious metals required.

Photocatalytic converters: These systems use light-activated catalysts to break down pollutants, offering the potential for improved low-temperature performance.

Thermoelectric generators: By converting waste heat from the exhaust into electricity, these devices could improve overall vehicle efficiency while also assisting in emissions reduction.

Advanced sensor technologies: Real-time monitoring of exhaust composition allows for more precise control of the combustion process and catalytic reactions, potentially improving efficiency and reducing emissions.

The Road Ahead: Catalytic Converters in the Age of Electrification

As the automotive industry shifts towards electrification, the role of catalytic converters is evolving. While fully electric vehicles don't require catalytic converters, hybrid vehicles still rely on this technology for their internal combustion components. Additionally, the increasing popularity of fuel cell vehicles presents new challenges and opportunities in emissions control.

For hydrogen fuel cell vehicles, catalytic converters play a crucial role in ensuring the purity of the hydrogen fuel and managing any potential emissions. These systems often use platinum-based catalysts, similar to traditional converters, but optimized for the unique requirements of fuel cell technology.

Even as alternative propulsion technologies gain ground, internal combustion engines are likely to remain a significant part of the global vehicle fleet for years to come, particularly in developing markets. This means that ongoing research and development in catalytic converter technology will continue to be vital for global air quality improvement efforts.

Conclusion: A Legacy of Cleaner Air

The catalytic converter stands as a testament to the power of innovative engineering in addressing environmental challenges. From its humble beginnings in the 1950s to its near-universal adoption in modern vehicles, this device has played a crucial role in reducing vehicle emissions and improving air quality in cities around the world.

As we look to the future, the principles behind catalytic converters – the use of catalysts to facilitate beneficial chemical reactions – continue to inspire new approaches to environmental protection. Whether it's in next-generation vehicles, industrial processes, or even in capturing and converting atmospheric carbon dioxide, the legacy of the catalytic converter extends far beyond the automotive world.

While challenges remain, particularly in terms of resource use and adapting to new propulsion technologies, the ongoing evolution of catalytic converter technology demonstrates the automotive industry's commitment to reducing its environmental impact. As consumers, policymakers, and engineers, we all have a role to play in supporting and advancing these efforts towards cleaner, more sustainable transportation.

In the end, the catalytic converter reminds us that even small, hidden components can have a massive impact on our world. It stands as a shining example of how human ingenuity, driven by environmental concern, can create solutions that benefit us all through cleaner air and a healthier planet.