Introduction: The Unsung Hero of Sanitation

Every day, billions of people around the world use toilets without giving much thought to the ingenious system working behind the scenes. At the heart of this marvel of modern sanitation lies the cistern – a seemingly simple yet remarkably efficient device that manages our waste with each flush. In this comprehensive exploration, we'll dive deep into the inner workings of cisterns, unraveling the mysteries of inlet valves, float mechanisms, and the intricate dance of hydraulics that keeps our bathrooms functioning smoothly.

The Cistern: A Brief Overview

A cistern, in the context of toilet technology, is essentially a water storage tank typically mounted above or behind the toilet bowl. Its primary function is to hold a reservoir of water that can be rapidly released to flush waste from the bowl. While the concept may seem straightforward, the mechanics inside are cleverly designed to maintain water levels and initiate the flushing process with precision.

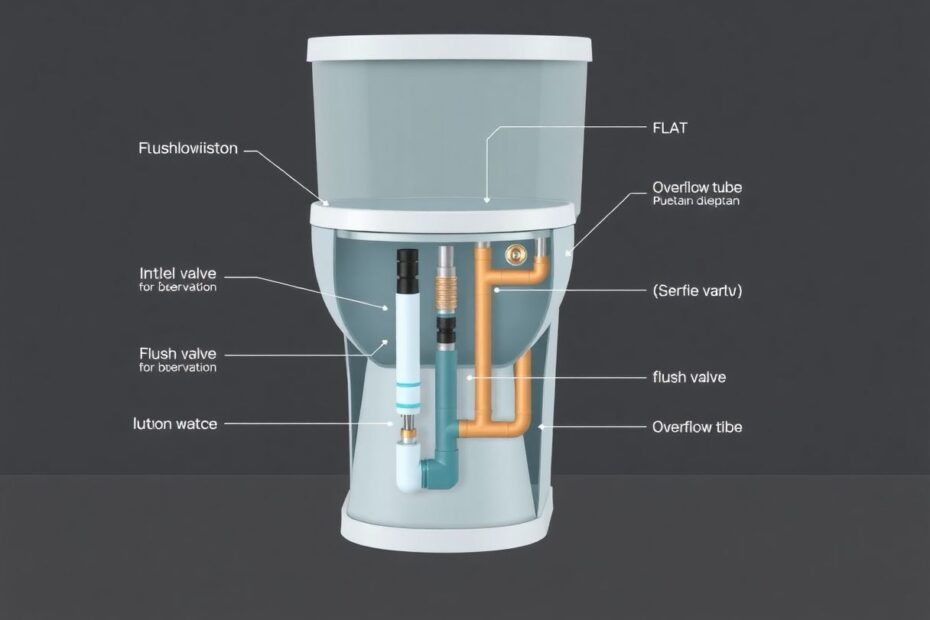

Anatomy of a Cistern: Breaking Down the Components

To truly understand how a cistern works, we need to familiarize ourselves with its key components. Let's take a closer look at the parts that make up this essential plumbing fixture:

The Tank

The tank is the main body of the cistern, typically made of vitreous china or plastic. It serves as the water container, holding anywhere from 1.28 to 1.6 gallons (4.8 to 6 liters) in modern, water-efficient models. The tank's capacity is crucial for providing enough water volume and pressure for effective flushing.

The Inlet Valve (Fill Valve)

The inlet valve, also known as the fill valve, is perhaps the most critical component of the cistern. It controls the flow of water into the tank, ensuring that it maintains the correct water level. Modern inlet valves are marvels of precision engineering, capable of shutting off water flow within fractions of a millimeter of the desired water level.

The Float

Working in tandem with the inlet valve is the float. This buoyant device rises and falls with the water level, signaling the inlet valve when to open or close. Traditionally, this was a ball float on an arm, but modern designs often use more compact cup floats or electronic sensors.

The Flush Valve

The flush valve is the mechanism that releases water from the tank into the bowl when activated. It's typically a flapper or canister-style valve that lifts to allow water to rush through the flush valve opening.

The Overflow Tube

As a safety feature, the overflow tube prevents the tank from overfilling by directing excess water into the bowl if the inlet valve fails to shut off.

The Flush Lever

This is the external handle or button that initiates the flushing process. When activated, it lifts the flush valve, starting the chain of events that leads to a flush.

The Intricate Workings of the Inlet Valve

The inlet valve is a masterpiece of hydraulic engineering, and understanding its operation is key to appreciating the cistern's functionality. Here's a detailed look at how it works:

When the cistern is empty or partially filled, the inlet valve is open, allowing water to flow in from the main supply line. This water enters under pressure, typically around 45-80 psi (310-552 kPa) in residential settings.

As the water level rises, it lifts the float. In modern designs, this float is often integrated into the valve assembly itself, making for a more compact and efficient mechanism.

When the float reaches a predetermined height, corresponding to the desired water level in the tank, it triggers the inlet valve to close. This closure is often achieved through a lever mechanism or, in more advanced models, a diaphragm that responds to water pressure.

The precision of this mechanism is remarkable. High-quality inlet valves can maintain water levels within a range of ±0.125 inches (3.175 mm), ensuring consistent flush performance.

If the water level drops due to evaporation or a small leak, the float lowers slightly, reopening the valve to top up the tank. This self-regulating feature maintains the cistern's readiness for the next flush.

As a fail-safe, if the inlet valve malfunctions and fails to close, water will flow into the overflow tube and into the bowl, preventing flooding. This overflow typically begins when the water level reaches about 1 inch (25.4 mm) below the top of the tank.

Types of Inlet Valves: A Technological Evolution

The design of inlet valves has evolved significantly over the years, with each iteration bringing improvements in efficiency, reliability, and water conservation. Let's explore some of the most common types:

Ball Cock Valve

This is the traditional design, featuring a floating ball on an arm. As the water level rises, the ball floats up, eventually shutting off the water supply. While simple and reliable, these valves are being phased out in favor of more efficient designs.

Diaphragm Valve

Diaphragm valves use water pressure to control a flexible diaphragm, which opens and closes the water inlet. These valves are known for their quiet operation and ability to function well even with low water pressure.

Float Cup Valve

A more modern and compact design, the float cup valve features a floating cup that surrounds the valve mechanism. As the cup rises with the water level, it closes the valve. These are increasingly common in new installations due to their reliability and space-saving design.

Pilot Valve

The pilot valve is a sophisticated two-stage system that offers precise control over water flow. It uses a small pilot valve to control the operation of the main valve, allowing for very accurate water level management.

Electronic Sensor Valve

At the cutting edge of cistern technology, electronic sensor valves use pressure sensors or capacitive sensing to detect water levels and control the inlet valve. These offer the highest precision and can be integrated into smart home systems for advanced water management.

The Flushing Process: A Hydraulic Symphony

When you activate the flush, a carefully choreographed sequence of events unfolds:

The flush lever lifts the flush valve, opening the connection between the cistern and bowl. This action requires overcoming the water pressure holding the valve closed, typically around 0.5-1 psi (3.4-6.9 kPa).

Water rushes from the cistern into the bowl through rim holes and a larger hole called the siphon jet. This initial rush of water creates a surge that can reach flow rates of up to 3 gallons per second (11.4 liters per second).

The rapid water flow creates a siphon effect in the bowl. As the water level in the bowl rises, it reaches the top of the trapway, a curved section of the drain. Once water starts flowing down the far side of the trapway, it creates a vacuum effect that pulls the rest of the bowl's contents with it.

This siphon effect is powerful enough to overcome the air lock in the trapway, which normally prevents sewer gases from entering the bathroom. The vacuum created can exert a force equivalent to about 14.7 psi (101.3 kPa), the standard atmospheric pressure at sea level.

As the cistern empties, the float drops, opening the inlet valve. Modern cisterns are designed to refill in about 30-60 seconds, balancing the need for quick readiness with water conservation.

The bowl refills through a small tube, restoring the water seal that prevents sewer gases from escaping. This refill is carefully calibrated to provide just enough water to seal the trapway without wasting excess.

Water Conservation Features: Engineering for Sustainability

As global water scarcity becomes an increasingly pressing issue, cistern technology has adapted to prioritize conservation. Modern cisterns incorporate several water-saving features:

Dual Flush Systems

Dual flush toilets offer two flush options: a full flush for solid waste (typically 1.6 gallons or 6 liters) and a reduced flush for liquid waste (usually around 0.8 gallons or 3 liters). This can result in water savings of up to 67% compared to older, single-flush models.

Adjustable Fill Height

Many modern cisterns allow for adjustment of the fill height, enabling users to fine-tune water usage. Lowering the fill height by just 0.5 inches (12.7 mm) can save up to 0.25 gallons (0.95 liters) per flush.

Delayed Fill

Some advanced cisterns incorporate a delayed fill mechanism, which waits until the flush is complete before refilling. This ensures that all the water in the tank is used for flushing, rather than some being lost to early refilling.

Pressure-Assisted Flushing

While not strictly a water-saving feature, pressure-assisted cisterns use compressed air to enhance flushing power. This allows for effective waste removal with less water, typically using 1.1 to 1.28 gallons (4.2 to 4.8 liters) per flush.

Troubleshooting Common Cistern Issues

Understanding the mechanics of cisterns can be invaluable when diagnosing common toilet problems:

Running Toilet

A running toilet is often caused by a faulty flush valve that doesn't seal properly, allowing water to continuously flow into the bowl. It can also be due to a misadjusted fill valve that doesn't shut off at the correct water level. This issue can waste up to 200 gallons (757 liters) of water per day if left unchecked.

Weak Flush

A weak flush may be due to a low water level in the tank or partially clogged rim holes. Ensuring the water level is set correctly (usually about 1 inch or 25.4 mm below the top of the overflow tube) and cleaning the rim holes can often resolve this issue.

Slow Fill

Slow filling can indicate a problem with water pressure or a partially closed inlet valve. Most cisterns are designed to refill in 30-60 seconds; if it's taking significantly longer, it may be time to check the inlet valve or your home's water pressure.

Noisy Fill

A noisy fill cycle might suggest wear in the inlet valve or excessively high water pressure. Modern inlet valves are designed to operate quietly, with noise levels typically below 20 decibels.

The Evolution of Cistern Technology

The history of cistern technology is a fascinating journey of innovation:

Early Designs

The first cisterns were high-mounted tanks that used gravity for flushing power. These could be found in homes as early as the late 19th century and often held several gallons of water.

Low-Level Cisterns

As plumbing technology advanced, low-level cisterns became popular for their more discreet appearance. These were mounted directly on the toilet bowl and became the standard in many homes by the mid-20th century.

Close-Coupled Units

The next evolution was the close-coupled toilet, which integrated the cistern with the bowl for a sleeker look. This design, which emerged in the 1980s, remains popular today.

Concealed Cisterns

For ultra-modern bathrooms, concealed cisterns hidden within walls became a trend in the late 20th century. These offer a minimalist aesthetic while maintaining full functionality.

Smart Cisterns

The latest development in cistern technology incorporates sensors and electronics for improved efficiency. These smart systems can detect leaks, optimize water usage, and even integrate with home automation systems.

Environmental Impact and Future Trends

As we look to the future, cistern technology continues to evolve with a focus on sustainability:

Ultra-Low Flush Models

The latest ultra-low flush toilets use less than 1.28 gallons (4.8 liters) per flush, with some models achieving effective flushes with as little as 0.8 gallons (3 liters).

Greywater Systems

Innovative greywater systems are being developed that use recycled water from sinks or showers to fill cisterns, potentially saving thousands of gallons of freshwater per household annually.

Vacuum-Assisted Flushing

Vacuum-assisted toilets, common in aircraft and some commercial settings, are beginning to enter the residential market. These systems use negative air pressure to enhance flush power while using minimal water.

Waterless Solutions

For extreme water conservation, waterless toilets such as composting toilets are gaining traction. While not suitable for all situations, these can save up to 20,000 gallons (75,708 liters) of water per person per year compared to traditional flush toilets.

Conclusion: The Future of Flush

The humble cistern, often overlooked, is a testament to human ingenuity in hydraulic engineering. From the precise operation of the inlet valve to the powerful siphon effect of the flush, every component plays a crucial role in managing our waste efficiently and hygienically.

As we face increasing water scarcity and environmental challenges, understanding and improving upon cistern technology will be key to developing sustainable sanitation solutions. The toilets of the future may look quite different from those we use today, but they will undoubtedly build upon the principles pioneered in the classic cistern design.

Whether you're a homeowner troubleshooting a toilet issue, a plumber honing your craft, or simply someone curious about the inner workings of everyday objects, appreciating the complexity and efficiency of the cistern can give you a new perspective on this essential fixture. The next time you hear that familiar sound of a refilling tank, you'll know the intricate dance of valves, floats, and water pressure working behind the scenes to keep your bathroom running smoothly.

In the grand scheme of human innovations, the cistern may not receive the same acclaim as smartphones or space rockets. However, its impact on public health, water management, and quality of life is immeasurable. As we continue to refine and reimagine this technology, we move closer to a future where efficient sanitation and water conservation go hand in hand, ensuring a cleaner, healthier world for generations to come.