Heat exchangers are marvels of engineering that surround us in our daily lives, yet often go unnoticed. These devices play a crucial role in countless applications, from keeping our homes comfortable to powering industrial processes. In this comprehensive guide, we'll dive deep into the world of heat exchangers, exploring their inner workings, diverse types, and the profound impact they have on our modern world.

Understanding the Basics: What Is a Heat Exchanger?

At its core, a heat exchanger is a device designed to transfer thermal energy between two or more fluids at different temperatures. The beauty of this process lies in its ability to achieve this heat transfer without the fluids coming into direct contact with each other. This separation is crucial in many applications where mixing of fluids would be undesirable or even dangerous.

To grasp the concept, imagine two streams of water—one hot and one cold—flowing through adjacent pipes. The heat from the hot water naturally wants to move towards the colder water. A heat exchanger facilitates this transfer efficiently, allowing the hot stream to cool down while the cold stream warms up. This simple principle forms the foundation of all heat exchangers, regardless of their complexity or specific design.

The Science Behind Heat Transfer

To truly appreciate how heat exchangers function, we need to understand the fundamental mechanisms of heat transfer. There are three primary modes through which heat can be transferred:

Conduction: This occurs when heat moves through a solid material. In heat exchangers, conduction happens through the walls of pipes or plates separating the fluids.

Convection: This involves the transfer of heat by the movement of fluids. As fluids flow through a heat exchanger, they carry heat energy with them, creating convection currents that enhance heat transfer.

Radiation: While less significant in most heat exchangers, radiation involves the transfer of heat through electromagnetic waves. This mode becomes more relevant in high-temperature applications.

In most heat exchangers, conduction and convection are the dominant modes of heat transfer. The efficiency of these processes is governed by several factors, including the thermal conductivity of materials, fluid flow rates, and the temperature difference between the fluids.

Key Principles of Heat Exchanger Operation

Surface Area: The More, The Merrier

One of the fundamental principles in heat exchanger design is maximizing the surface area available for heat transfer. This is why you'll often see heat exchangers with intricate designs featuring multiple tubes, plates, or fins. The greater the surface area in contact with the fluids, the more efficient the heat transfer process becomes.

For instance, a car radiator uses a network of thin tubes with attached fins to increase the surface area exposed to the air. This design allows for rapid heat dissipation from the engine coolant to the surrounding air, keeping the engine at an optimal operating temperature.

Flow Configuration: Direction Matters

The way fluids flow relative to each other within a heat exchanger significantly impacts its efficiency. There are three primary flow configurations:

Parallel Flow: Both fluids move in the same direction. While simple to design, this configuration is generally less efficient.

Counter Flow: The fluids move in opposite directions. This arrangement maintains the largest temperature difference between the fluids throughout the exchanger, making it the most efficient configuration.

Cross Flow: The fluids flow perpendicular to each other. This setup offers a good balance between efficiency and design simplicity, making it popular in many applications.

Each configuration has its advantages and is chosen based on specific application requirements, space constraints, and desired efficiency levels.

Types of Heat Exchangers: A Diverse Family

The world of heat exchangers is rich with diversity, each type tailored to specific needs and applications. Let's explore some of the most common types:

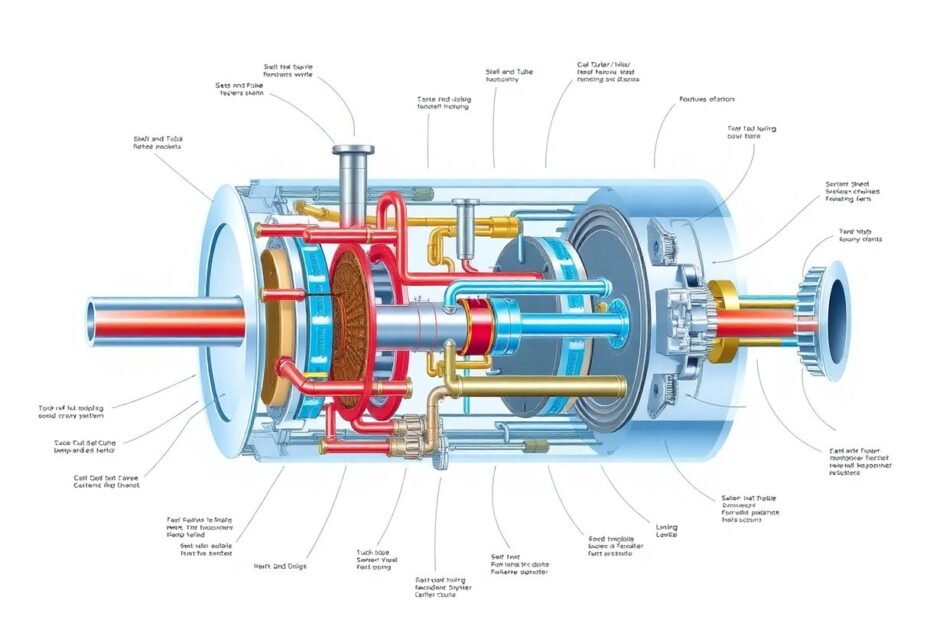

Shell and Tube Heat Exchangers

Perhaps the most recognizable type, shell and tube heat exchangers consist of a bundle of tubes enclosed within a cylindrical shell. One fluid flows through the tubes while the other flows around them within the shell. This design is highly versatile and can handle high pressures and temperatures, making it a favorite in oil refineries and large chemical plants.

Plate Heat Exchangers

Plate heat exchangers use a series of thin, corrugated plates to separate the fluids. The corrugations increase turbulence and surface area, enhancing heat transfer efficiency. These exchangers are compact and easily disassembled for cleaning, making them ideal for food processing and pharmaceutical applications where hygiene is paramount.

Fin and Tube Heat Exchangers

Common in HVAC systems and automotive radiators, fin and tube exchangers feature tubes with attached fins to increase surface area. This design is particularly effective when one of the fluids is a gas, as the fins help compensate for the poor heat transfer characteristics of gases.

Air-Cooled Heat Exchangers

These exchangers use ambient air to cool a fluid flowing through finned tubes. They're often seen in power plants and industrial facilities where water for cooling is scarce or expensive.

Regenerative Heat Exchangers

Unique in their operation, regenerative heat exchangers use a rotating wheel or matrix to transfer heat between two fluid streams. As the wheel rotates, it absorbs heat from the hot stream and releases it to the cold stream. This type is commonly used in air preheaters for large boilers and in HVAC systems for energy recovery.

Applications Across Industries

The versatility of heat exchangers makes them indispensable across a wide range of industries:

Automotive Industry

In cars, heat exchangers are everywhere. The radiator cools the engine, the intercooler enhances engine performance in turbocharged vehicles, and the heater core provides warmth to the cabin.

HVAC and Refrigeration

Air conditioners, refrigerators, and heat pumps all rely on heat exchangers to transfer heat between refrigerants and the environment. The evaporator and condenser in these systems are both types of heat exchangers.

Power Generation

In power plants, heat exchangers play critical roles in steam generation, condensation, and cooling processes. Boilers, condensers, and cooling towers are all specialized forms of heat exchangers.

Chemical and Process Industries

Chemical plants use heat exchangers for heating, cooling, condensation, and evaporation processes. The ability to precisely control temperatures is crucial for many chemical reactions and separations.

Food and Beverage Production

Pasteurization, sterilization, and brewing processes all rely on heat exchangers to maintain precise temperature control, ensuring food safety and quality.

Aerospace

Aircraft use heat exchangers in their environmental control systems to regulate cabin temperature and in their engines to cool oil and hydraulic fluids.

The Mathematics of Heat Exchange

For engineers and scientists, understanding the mathematical principles behind heat exchangers is crucial. The fundamental equation governing heat transfer in these devices is:

Q = U * A * ΔTLM

Where:

- Q is the rate of heat transfer

- U is the overall heat transfer coefficient

- A is the heat transfer surface area

- ΔTLM is the log mean temperature difference

This equation encapsulates the relationship between heat transfer rate, exchanger design (through U and A), and the temperature profiles of the fluids (represented by ΔTLM).

The effectiveness (ε) of a heat exchanger, a measure of its performance, is given by:

ε = Actual heat transfer / Maximum possible heat transfer

This ratio, always between 0 and 1, provides a quick way to assess how close a heat exchanger is performing to its theoretical maximum.

Challenges and Innovations

While heat exchangers are well-established technology, engineers and researchers continue to push the boundaries of their performance and efficiency:

Fouling: The Persistent Enemy

Fouling, the accumulation of unwanted deposits on heat transfer surfaces, is a significant challenge. It reduces efficiency and can lead to corrosion. Innovations in self-cleaning surfaces and advanced materials aim to mitigate this issue.

Miniaturization

As devices become smaller and more compact, there's a growing need for miniaturized heat exchangers. Microchannels and advanced manufacturing techniques like 3D printing are enabling the creation of incredibly compact yet efficient heat exchangers.

Smart Heat Exchangers

The integration of sensors and control systems is giving rise to "smart" heat exchangers that can adapt to changing conditions in real-time, optimizing performance and energy efficiency.

Advanced Materials

Research into nanomaterials and composites is opening new possibilities for heat exchanger design. Materials with exceptional thermal conductivity or unique phase-change properties could revolutionize heat transfer efficiency.

Environmental Impact and Sustainability

Heat exchangers play a crucial role in improving energy efficiency across industries. By recovering waste heat and optimizing thermal processes, they contribute significantly to reducing energy consumption and, consequently, greenhouse gas emissions.

In renewable energy systems, heat exchangers are essential components. Solar thermal collectors, geothermal power plants, and biomass facilities all rely on efficient heat exchange to convert natural energy sources into usable power.

The Future of Heat Exchangers

As we look to the future, several exciting trends are shaping the evolution of heat exchanger technology:

Integration with AI and IoT: Smart heat exchangers will become more common, using artificial intelligence to predict maintenance needs and optimize performance in real-time.

Biomimicry: Engineers are looking to nature for inspiration, studying how living organisms manage heat transfer to create more efficient designs.

Phase-Change Materials: The incorporation of materials that can store and release large amounts of energy during phase transitions could lead to more efficient and compact heat exchangers.

Additive Manufacturing: 3D printing technologies are enabling the creation of complex geometries that were previously impossible, potentially revolutionizing heat exchanger design.

Conclusion: The Unsung Heroes of Modern Technology

Heat exchangers, though often overlooked, are truly the unsung heroes of our technological world. From the smallest electronic device to the largest power plant, these ingenious devices keep our systems running efficiently and our environments comfortable.

As we continue to push the boundaries of technology and seek more sustainable solutions to our energy needs, the role of heat exchangers will only grow in importance. Their ability to transfer heat efficiently is not just a matter of engineering elegance; it's a crucial factor in our efforts to conserve energy and reduce our environmental impact.

Whether you're a student of engineering, a professional in industry, or simply curious about the technology that shapes our world, understanding heat exchangers offers a fascinating glimpse into the intricate systems that power modern life. As we look to the future, these devices will continue to evolve, becoming smarter, more efficient, and more integrated into the fabric of our technological landscape.

The world of heat exchangers is a testament to human ingenuity and our ability to harness the fundamental laws of nature for practical purposes. As we face the challenges of the 21st century, from climate change to energy scarcity, the humble heat exchanger stands ready to play its part in building a more sustainable and efficient future.