Outboard motors have revolutionized the way we navigate waterways, transforming recreational boating, fishing, and even commercial marine operations. These compact powerhouses combine ingenious engineering with practical design to propel vessels across lakes, rivers, and oceans. In this comprehensive guide, we'll dive deep into the inner workings of outboard motors, exploring their history, mechanics, and the cutting-edge innovations shaping their future.

The Evolution of Outboard Motors: From Humble Beginnings to High-Tech Marvels

The story of outboard motors begins in the late 19th century, with Gustave Trouvé's pioneering electric outboard in the 1870s. However, it was Ole Evinrude's 1909 patent for a practical gasoline-powered outboard that truly launched the industry. Since then, outboard motors have undergone a remarkable transformation, driven by advances in engineering and changing environmental concerns.

The post-World War II era saw rapid advancements in outboard technology, with manufacturers like Mercury, Johnson, and Yamaha pushing the boundaries of power and efficiency. The 1960s and 1970s brought more powerful engines, while the 1990s ushered in a new focus on environmental friendliness and fuel efficiency.

Today's outboard motors are technological marvels, boasting features that would have seemed like science fiction to early pioneers. From electronic fuel injection to joystick controls and artificial intelligence, modern outboards represent the cutting edge of marine propulsion technology.

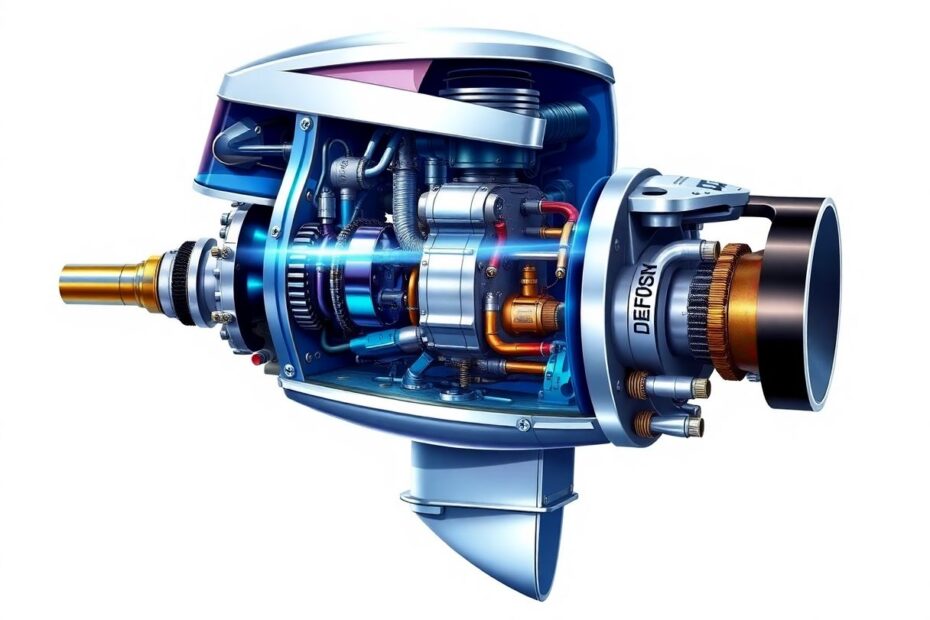

The Anatomy of an Outboard Motor: A Symphony of Moving Parts

At its core, an outboard motor is a self-contained unit that combines an engine, gearbox, and propeller. This design offers several advantages over inboard engines, including easy installation, removal, and maintenance. Let's break down the key components and how they work together to propel a boat through water.

The Engine: The Heart of the Outboard

The engine is the powerhouse of any outboard motor. Most modern outboards use four-stroke internal combustion engines, similar to those found in automobiles but optimized for marine use. These engines operate on a four-step cycle:

- Intake: The piston moves down, drawing in a mixture of fuel and air.

- Compression: The piston moves up, compressing the fuel-air mixture.

- Combustion: A spark plug ignites the compressed mixture, driving the piston down.

- Exhaust: The piston moves up again, expelling the burnt gases.

This cycle repeats thousands of times per minute, generating the power needed to propel the boat. Modern outboard engines can produce anywhere from 2.5 to over 600 horsepower, depending on their size and design.

The Power Transfer System: From Engine to Propeller

Once the engine generates power, it needs to be transferred efficiently to the propeller. This is accomplished through a series of components:

- The crankshaft converts the up-and-down motion of the pistons into rotational motion.

- A long vertical driveshaft carries power from the crankshaft down to the lower unit.

- In the lower unit, a gearbox changes the direction of rotation from vertical to horizontal and adjusts the speed for optimal propeller performance.

- Finally, the propeller shaft connects the gearbox to the propeller itself.

This system ensures that the engine's power is effectively translated into propulsive force in the water.

The Propeller: Where Power Meets Water

The propeller is perhaps the most crucial component of an outboard motor, as it's responsible for converting the engine's power into forward motion. Propeller design is a complex science, balancing factors like the number of blades (typically 3 or 4), pitch (the theoretical distance the propeller would move forward in one revolution), and diameter.

As the propeller rotates, it creates a pressure difference between its front and back surfaces. This pressure differential generates thrust, pushing water backwards and propelling the boat forward. The efficiency of this process depends on factors like propeller design, engine power, and boat hull shape.

Advanced Features: Steering, Cooling, and Fuel Systems

Modern outboard motors incorporate a range of advanced features that enhance their performance, efficiency, and ease of use.

Steering and Trim: Precision Control on the Water

One of the key advantages of outboard motors is their integrated steering system. The entire motor unit pivots to direct thrust, allowing for precise control. Larger outboards often use hydraulic steering systems for effortless maneuvering, while smaller models may feature manual tiller control.

The ability to adjust the motor's trim (vertical angle) is another crucial feature. By tilting the motor up or down, boaters can optimize their vessel's performance for different speeds and water conditions. This affects not only speed and fuel efficiency but also handling and comfort.

Cooling Systems: Battling the Heat

Operating in a marine environment presents unique challenges for engine cooling. Most outboard motors use an open cooling system, drawing in water from their surroundings to cool the engine. This ingenious design eliminates the need for a radiator and uses the body of water the boat is in as a massive heat sink.

Here's how it works:

- Water is drawn in through intakes near the gearbox.

- It's circulated through the engine to absorb heat.

- The heated water is then expelled, often visible as a telltale stream behind the boat.

This system is both simple and effective, though it requires regular flushing with fresh water after use in saltwater to prevent corrosion.

Fuel Systems: Powering the Engine

Modern outboard motors typically feature sophisticated fuel systems designed for efficiency and reliability. Many now use direct fuel injection, where fuel is sprayed directly into the combustion chamber under high pressure. This technology offers several advantages:

- Improved fuel efficiency

- Reduced emissions

- Better cold-starting performance

- Increased power output

Some high-end outboards even incorporate computer-controlled fuel injection systems that continuously optimize the fuel-air mixture based on operating conditions.

Environmental Considerations: Greening the Blue

As awareness of environmental issues has grown, outboard motor manufacturers have made significant strides in reducing their products' environmental impact. These efforts focus on several key areas:

Emissions reduction: Stricter regulations have led to the development of cleaner-burning engines. Four-stroke and direct injection technologies have dramatically reduced harmful emissions compared to older two-stroke designs.

Noise pollution: Modern outboards are significantly quieter than their predecessors, reducing disturbance to marine life and enhancing the boating experience.

Fuel efficiency: Improved engine designs and advanced fuel injection systems have increased fuel efficiency, reducing both operating costs and carbon footprint.

Alternative fuels: Some outboards can now run on biodiesel or other eco-friendly fuels, offering environmentally conscious boaters more sustainable options.

The Future of Outboard Motors: Innovation on the Horizon

The outboard motor industry continues to evolve, with several exciting developments on the horizon:

Electric outboards: Advances in battery technology are making electric propulsion increasingly viable for marine applications. Companies like Torqeedo and ePropulsion are leading the charge, offering quiet, zero-emission alternatives to traditional gasoline-powered outboards.

Hybrid systems: Some manufacturers are exploring hybrid outboard systems that combine the benefits of electric and gasoline power. These systems could offer the range and power of traditional outboards with the clean, quiet operation of electric motors.

Advanced materials: The use of lightweight, high-strength materials like carbon fiber and advanced alloys could lead to more efficient, powerful outboards.

Artificial intelligence: Smart systems that optimize performance based on conditions are becoming a reality. These AI-driven outboards could automatically adjust trim, fuel mixture, and other parameters for maximum efficiency and performance.

Choosing and Maintaining Your Outboard Motor

Selecting the right outboard motor depends on various factors, including boat size, intended use, and budget. Consider the following when making your choice:

- Power requirements: Ensure the motor provides adequate power for your boat size and typical load.

- Fuel efficiency: Look for models with advanced fuel injection systems for better economy.

- Reliability: Research customer reviews and reliability ratings, especially for offshore use.

- Maintenance requirements: Consider long-term costs and ease of servicing.

- Environmental impact: Choose models with lower emissions and noise levels if environmental concerns are a priority.

Once you've selected your outboard, proper maintenance is key to ensuring its longevity and performance:

- Regular oil changes are essential for four-stroke engines.

- Use fresh fuel and appropriate additives to keep the fuel system clean.

- Flush with fresh water after use in saltwater to prevent corrosion.

- Properly winterize your outboard during the off-season to prevent damage.

- Schedule annual professional servicing to catch and address potential issues early.

Conclusion: The Enduring Appeal of Outboard Motors

Outboard motors have come a long way since their invention over a century ago. Their combination of power, portability, and ease of use continues to make them a popular choice for boat owners worldwide. As technology advances, we can expect outboard motors to become even more efficient, environmentally friendly, and user-friendly.

Whether you're a seasoned boater or considering your first marine engine, understanding how outboard motors work can enhance your appreciation of these remarkable machines and help you make informed decisions about their use and care. As we look to the future, it's clear that outboard motors will continue to play a crucial role in our exploration and enjoyment of the world's waterways, evolving to meet the challenges of a changing world while retaining the spirit of innovation that has driven their development for over a century.