Introduction: The Unsung Heroes of Office Productivity

In the bustling landscape of modern offices, schools, and libraries, there's a device that often goes unnoticed until it's desperately needed – the humble photocopier. These machines, capable of reproducing documents at the push of a button, have revolutionized the way we handle paperwork and information dissemination. But have you ever paused to consider the intricate dance of physics, chemistry, and engineering that occurs each time you make a copy? Let's embark on a journey into the heart of these marvels of technology and uncover the science that makes document duplication possible.

The Fundamental Principles: Static Electricity and Photoconductivity

At the core of photocopier technology lie two key scientific principles: static electricity and photoconductivity. These phenomena, which might seem like relics of high school physics classes, are the bedrock upon which the entire copying process is built.

Static Electricity: Nature's Adhesive

Static electricity is a phenomenon we've all encountered, often in amusing or startling ways. It's the force that makes your hair stand on end when you rub a balloon against it, or causes that tiny shock when you touch a doorknob after shuffling across a carpeted floor. But in photocopiers, this force is harnessed with precision to create perfect copies.

At its most basic, static electricity occurs when there's an imbalance of electric charges within or on the surface of a material. This imbalance can be created by the transfer of electrons from one object to another. In photocopiers, this principle is used to control the placement of toner – the fine powder that forms the images on your copies.

Photoconductivity: When Light Meets Electricity

The second crucial principle is photoconductivity, a property exhibited by certain materials that become more electrically conductive when exposed to light. This might sound like science fiction, but it's a real and measurable effect that forms the basis of the photocopying process.

In the early days of photocopier technology, the element selenium was often used as a photoconductor due to its excellent ability to transform light patterns into electrical patterns. Modern photocopiers might use organic photoconductors or other advanced materials, but the basic principle remains the same: light hitting the photoconductor creates an electrical pattern that corresponds to the image being copied.

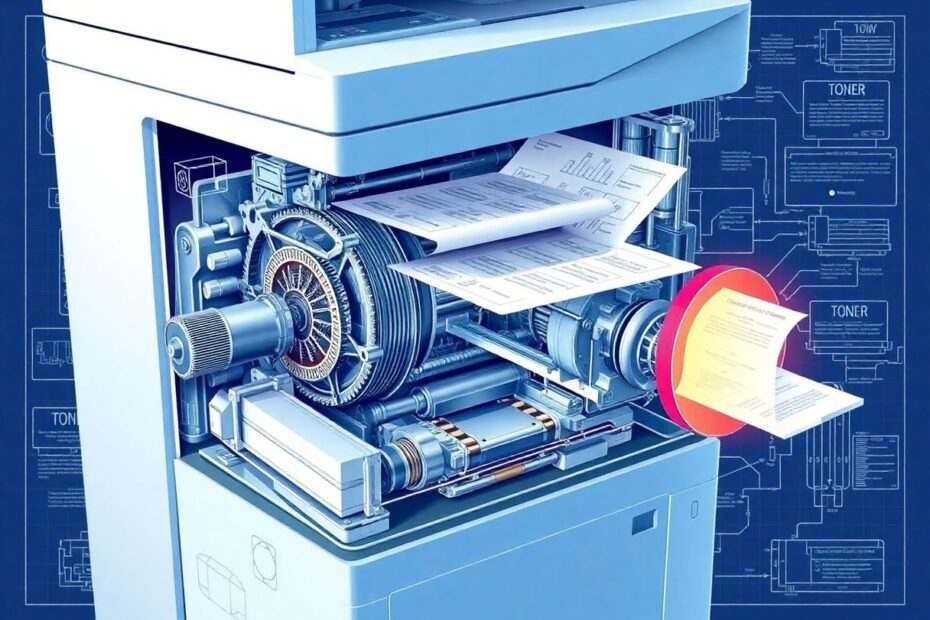

The Photocopying Process: A Step-by-Step Journey

Now that we understand the basic principles, let's walk through the photocopying process, step by step. This journey from original document to fresh copy is a testament to human ingenuity and the practical application of scientific principles.

1. Document Placement and Scanning

The process begins when you place your original document face-down on the glass surface of the copier. When you press the start button, a bright light begins to move across the document, illuminating it section by section. This light is typically provided by a xenon gas lamp or LED array, chosen for their ability to produce intense, consistent illumination.

As the light moves across the document, it's reflected differently by the light and dark areas of the page. White areas reflect more light, while dark areas with text or images absorb more light. This reflected light is then directed onto the photoconductor drum or belt through a series of mirrors and lenses.

2. Creating an Electrical Image

The heart of the photocopier is the photoconductor drum or belt. This component is coated with a material that becomes conductive when exposed to light. As the reflected light from the original document falls on the photoconductor, it creates a pattern of electrical charges that correspond to the light and dark areas of the original.

In areas where light hits the photoconductor (corresponding to white areas of the original), the electrical charge is neutralized. In dark areas (where text or images are present), the charge remains. This creates an invisible "electrical image" of the original document on the surface of the photoconductor.

3. Applying Toner

Once the electrical image is formed on the photoconductor, the copier applies toner to the drum or belt. Toner is a fine powder made up of pigment particles (usually carbon-based for black toner) mixed with plastic resin. These particles are given an electrical charge opposite to that of the areas on the photoconductor where the image should appear.

As the toner is applied, it's attracted to the charged areas of the photoconductor and repelled from the neutral areas. This creates a visible, powdery version of the original image on the drum or belt.

4. Transferring the Image

With the toner image now on the photoconductor, it's time to transfer it to paper. A blank sheet of paper is fed into the copier and given an electrical charge opposite to that of the toner particles. As the paper passes close to the photoconductor, the toner particles are attracted to the paper, jumping across the small gap and adhering to the paper's surface.

This transfer process is crucial and delicate. The strength of the electrical fields must be precisely controlled to ensure that all the toner transfers to the paper, leaving none behind on the photoconductor.

5. Fusing the Image

At this point, the toner is sitting loosely on the surface of the paper. To create a permanent copy, the toner needs to be fused to the paper. This is achieved by passing the paper through a pair of heated rollers.

These rollers, typically heated to temperatures between 350°F and 425°F (175°C to 218°C), melt the plastic component of the toner. The pressure from the rollers then pushes the melted toner into the fibers of the paper. As the paper exits the fuser, the toner cools and solidifies, creating a permanent bond with the paper.

6. Cleaning and Resetting

After the copy is complete, any residual toner on the photoconductor drum or belt needs to be removed to prepare for the next copy. This is typically done with a cleaning blade that scrapes off any remaining toner, which is then collected in a waste toner bottle.

The photoconductor is then exposed to a uniform light source to neutralize any remaining electrical charges, resetting it for the next copying cycle.

The Digital Revolution: Modern Photocopiers

While the basic principles of photocopying remain the same, modern machines have embraced digital technology, offering enhanced features and improved quality. Let's explore how digital photocopiers work and the advantages they offer.

The Digital Photocopying Process

Scanning: Instead of using light and mirrors to create an electrical image directly, digital copiers use a high-resolution scanner to capture the document as a digital image. This scanner typically uses a Charge-Coupled Device (CCD) or Contact Image Sensor (CIS) to convert the light reflected from the document into digital signals.

Processing: The scanned image is processed by a computer within the copier. This digital processing allows for a wide range of adjustments and enhancements, including:

- Contrast and brightness adjustment

- Image sharpening

- Color correction

- Resizing and repositioning

- Text recognition (OCR – Optical Character Recognition)

Printing: The processed digital image is then printed using technology similar to that of a laser printer. A laser beam, controlled by the digital image data, "draws" the image onto a photoconductor drum. From this point, the process is similar to traditional photocopying, with toner being applied to the drum and then transferred to paper.

Advantages of Digital Photocopiers

Digital technology has brought numerous advantages to photocopying:

Higher Quality: Digital copiers can produce sharper, clearer copies with better control over image density and contrast. The ability to process the image digitally allows for automatic or user-controlled enhancements that were impossible with analog systems.

More Features: Digital copiers often allow for sophisticated image editing, including resizing, combining multiple documents, adding watermarks, and even creating booklets. Many models also offer features like duplex (double-sided) copying and collating.

Multifunctionality: Many digital copiers serve as all-in-one office machines, combining the functions of a copier, printer, scanner, and fax machine. This consolidation of functions can save space and reduce the need for multiple devices.

Network Connectivity: Modern digital copiers can be connected to office networks, allowing users to send print jobs from their computers or even from remote locations. Some models also offer cloud connectivity, enabling direct scanning to cloud storage services.

Storage Capability: Digital copiers often have built-in hard drives or solid-state storage, allowing them to store scanned documents for future use or reprinting. This can be particularly useful for frequently used forms or documents.

Security Features: With growing concerns about data security, many digital copiers offer features like secure printing (where jobs are only released when the user enters a PIN at the machine), data encryption for stored documents, and user authentication to track copier usage.

The Evolution of Photocopier Technology

The journey from the first photocopier to today's advanced machines is a fascinating story of technological progress and human ingenuity. Let's trace this evolution and explore some key milestones in photocopier history.

The Birth of Xerography: Chester Carlson's Breakthrough

The story of the photocopier begins with Chester Carlson, an American physicist and patent attorney. Frustrated with the tedious process of making copies of patent specifications, Carlson set out to create a better way.

On October 22, 1938, in a makeshift lab in Astoria, Queens, Carlson and his assistant, Otto Kornei, created the world's first photocopy. Their setup was remarkably simple:

- A zinc plate coated with sulfur

- A glass slide with the words "10-22-38 ASTORIA" written on it

- A bright light

- A handkerchief

When they rubbed the sulfur-coated plate with the handkerchief to create a static charge, exposed it to bright light through the glass slide, and then sprinkled lycopodium powder (a fine dust made from club moss spores) on the plate, they found that the powder stuck to the areas that had been exposed to light, creating a copy of the text.

Carlson called his invention "electrophotography," which was later renamed "xerography" (from the Greek words for "dry writing"). This process formed the basis for all photocopiers for decades to come.

Key Milestones in Photocopier History

1949: The first commercial photocopier, the Xerox Model A, is introduced. It was far from user-friendly, requiring 39 steps to make a single copy, but it marked the beginning of a new era in document reproduction.

1959: Xerox releases the 914, the first fully automatic plain-paper copier. This machine was a massive commercial success, capable of making 100 copies per hour on plain paper. It weighed 648 pounds (294 kg) and occasionally had a tendency to catch fire, leading to the inclusion of a small fire extinguisher known as the "scorch eliminator."

1960s-1970s: Competition in the photocopier market intensifies, with companies like IBM, Kodak, and Canon entering the fray. This period saw rapid improvements in speed, reliability, and ease of use.

1970s: Color copiers begin to appear in the market, though they were initially very expensive and primarily used in specialized applications like graphic design and advertising.

1980s: The first digital copiers are developed, marking a significant leap in technology. These machines convert the image to digital form before printing, allowing for image processing and manipulation.

1990s-2000s: Multifunction devices combining copying, printing, scanning, and faxing become common in offices. Network connectivity becomes a standard feature, allowing copiers to serve as shared resources across office networks.

2010s-Present: Modern copiers incorporate advanced features like cloud connectivity, mobile printing, and sophisticated security measures. There's also a growing focus on environmental sustainability, with manufacturers working to reduce energy consumption and use more recyclable materials.

The Science Behind Toner: The Lifeblood of Photocopiers

Toner, the "ink" used in photocopiers and laser printers, is a crucial component of the copying process. Let's delve deeper into the science and technology behind this remarkable substance.

Composition of Toner

Toner is a fine, dry powder typically composed of four main ingredients:

Pigment: This provides the color. For black toner, the pigment is usually carbon black or a similar organic compound. Color toners use various pigments to achieve cyan, magenta, yellow, and black (CMYK).

Polymer: This is typically a plastic resin (often styrene-acrylic copolymer) that allows the toner to melt and fuse to the paper when heated.

Charge Control Agents: These additives help the toner particles hold an electrical charge, crucial for their attraction to the photoconductor drum and then to the paper.

Flow Control Additives: These help the toner particles flow smoothly and prevent clumping, ensuring even distribution during the copying process.

The exact composition can vary between manufacturers and is often a closely guarded trade secret.

How Toner Works: A Dance of Electrical Charges

The function of toner in a photocopier relies on precise control of electrical charges:

Charging: Toner particles are given an electrical charge, typically negative, by the copier's developer unit.

Attraction to Photoconductor: The charged toner is attracted to the oppositely charged areas on the photoconductor drum, which correspond to the dark areas of the original document.

Transfer to Paper: The paper is given a stronger positive charge, attracting the negatively charged toner particles away from the drum and onto the paper.

Fusing: Heat and pressure melt the polymer in the toner, bonding it permanently to the paper fibers.

Environmental Considerations and Innovations

As awareness of environmental issues grows, toner technology has evolved to become more eco-friendly:

Recyclable Cartridges: Many manufacturers now produce toner cartridges that can be easily recycled or refilled, reducing waste.

Plant-Based Toners: Some companies have developed toners made partially from plant-based materials, reducing reliance on petroleum-based plastics.

Lower Melting Points: Toners that melt at lower temperatures have been developed, reducing the energy required for the fusing process.

Reduced Particle Size: Smaller toner particles allow for higher resolution prints while using less material.

The Role of Paper in Photocopying: More Than Just a Canvas

While we often focus on the machine itself, the paper used in photocopying plays a crucial role in the quality of the final product. Let's explore the properties of paper that matter in photocopying and some of the specialized papers available.

Critical Paper Properties

Smoothness: The smoothness of paper is measured in Sheffield units, with lower numbers indicating smoother paper. Smoother paper generally produces clearer copies as the toner can adhere more evenly to the surface. However, extremely smooth papers can cause feeding issues in some copiers.

Brightness: Paper brightness is typically measured on a scale of 1 to 100, with higher numbers indicating brighter paper. Brighter paper provides better contrast, especially for text documents. Most standard copy paper has a brightness of 92-97.

Weight: Paper weight, measured in grams per square meter (gsm), affects how the paper handles in the copier. Standard copy paper is usually around 80 gsm. Heavier papers (100-120 gsm) are less likely to jam and can handle double-sided copying better, but may require special settings on the copier.

Moisture Content: The ideal moisture content for copy paper is between 4.7% and 5.5%. Paper with too much moisture can cause curling and feeding issues, while overly dry paper can lead to static buildup and paper jams.

Grain Direction: Paper fibers align in a particular direction during manufacturing. Paper with the grain running parallel to the feed direction generally performs better in copiers, reducing the likelihood of jams and curling.

Specialized Papers for Photocopying

Modern photocopiers can handle a variety of specialized papers, expanding their versatility:

Recycled Paper: Many copiers are designed to work well with recycled paper, supporting eco-friendly office practices. Recycled papers have improved significantly in quality and now often perform comparably to virgin fiber papers.

Glossy Paper: For high-quality image reproduction, especially in color copiers. These papers have a coating that allows for sharper, more vibrant images.

Card Stock: Heavier papers (usually 150-300 gsm) for producing sturdier documents like business cards or postcards. Many modern copiers have special trays or settings for handling these thicker papers.

Transparencies: Special plastic sheets for creating overhead projector slides. These require careful handling in the copier to prevent melting or jamming.

Textured Papers: Papers with intentional textures (like linen or laid finishes) can add a tactile and visual element to copies, though they may require adjustments to copier settings for optimal results.

Security Papers: These incorporate features like watermarks or color-changing inks to prevent unauthorized copying, useful for sensitive documents.

Color Photocopying: Adding Complexity and Vibrancy

Color photocopying adds several layers of complexity to the process we've discussed. Let's explore how color copiers work and the challenges they present.

The Color Photocopying Process

- Color Separation: The original image is scanned and digitally separated into four color components: Cyan, Magenta,