Introduction

In our digital age, where wireless technology and electronic transfers dominate, it's surprising to discover that many banks, hospitals, and large businesses still rely on a seemingly antiquated system for transporting physical items quickly and securely: pneumatic tubes. This ingenious technology, which harnesses the power of air pressure to propel objects through a network of tubes, has been a staple of efficient operations for over a century. In this article, we'll embark on an in-depth exploration of pneumatic tube transport, with a particular focus on their application in banking institutions. Join us as we unravel the science, history, and practical applications of this enduring and fascinating technology.

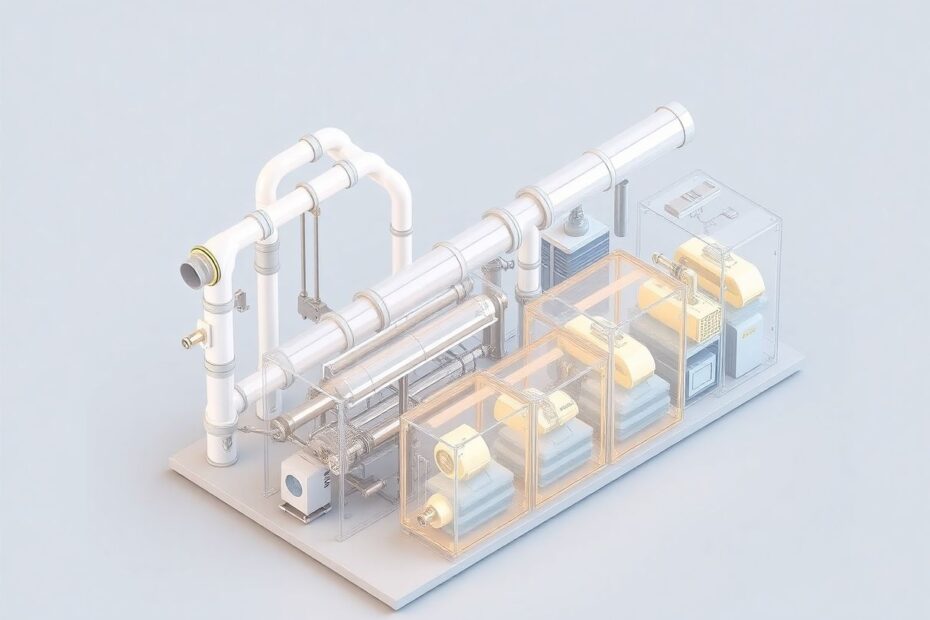

The Fundamentals of Pneumatic Tube Systems

What Are Pneumatic Tube Systems?

Pneumatic tube systems, also known as pneumatic tube transport (PTT), are a method of using compressed air or partial vacuum to propel cylindrical containers through a network of tubes. These systems are designed to transport physical objects, typically small items like cash, documents, or medical samples, from one location to another with speed and security.

Key Components of a Pneumatic Tube System

To understand how these systems function, it's essential to familiarize ourselves with their primary components:

Tubes: The backbone of the system, these are typically constructed from PVC plastic or lightweight metals such as aluminum. They form the network through which carriers travel.

Stations: These serve as both sending and receiving points in the network, where items are inserted or retrieved.

Carriers: Cylindrical containers that hold the items being transported. They are designed to fit snugly within the tubes while allowing for smooth movement.

Air Compressor: This crucial component provides the pneumatic power necessary to move carriers through the system.

Diverters: In more complex systems, these components direct carriers to different destinations within the network.

Control System: This manages the flow of carriers and regulates air pressure throughout the system, ensuring smooth and efficient operation.

The Science Behind Pneumatic Tube Transport

The Basic Principle: Differential Air Pressure

At its core, pneumatic tube systems operate on the principle of differential air pressure. By creating either higher pressure behind a carrier or lower pressure in front of it, the system can propel the carrier through the tubes with remarkable efficiency.

Here's a step-by-step breakdown of how a typical system operates:

- An item is placed into a carrier at a sending station.

- The carrier is inserted into the tube system.

- The control system activates the air compressor.

- Depending on the system design, the compressor either creates positive pressure behind the carrier, pushing it forward, or creates negative pressure (partial vacuum) in front of the carrier, effectively sucking it along.

- The carrier travels through the tube network at impressive speeds, typically ranging from 7 to 10 meters per second (about 15-22 mph).

- Upon approaching its destination, the carrier is slowed by an air cushion or mechanical brake to ensure a gentle arrival.

- The carrier reaches the receiving station, where the item can be retrieved.

Bernoulli's Principle in Action

To truly appreciate the elegance of pneumatic tube systems, we must consider Bernoulli's principle, a fundamental concept in fluid dynamics that plays a crucial role in their operation. Named after Swiss mathematician Daniel Bernoulli, this principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in pressure.

In the context of a pneumatic tube system:

- As air rushes past the carrier, its speed increases.

- This increase in speed creates an area of lower pressure around the carrier.

- The resulting difference in pressure between the front and back of the carrier helps to propel it forward, complementing the primary driving force of the compressed air or vacuum.

Overcoming Friction and Air Resistance

While air pressure drives the carrier forward, system designers must carefully account for forces working against its motion, primarily friction and air resistance. Factors that affect these opposing forces include:

- The smoothness of the tube interior

- The precision of the carrier's fit within the tube

- The shape and weight of the carrier

- The speed of airflow

By optimizing these factors, engineers can create systems that operate with maximum efficiency and reliability.

Pneumatic Tubes in Banking: A Closer Look

The Advantages of Pneumatic Tubes in Banking

Banks have been utilizing pneumatic tube systems for decades, and for good reason. These systems offer several key advantages that make them indispensable in the banking sector:

Enhanced Security: Cash and sensitive documents can be transported without human intervention, significantly reducing the risk of theft or loss.

Improved Efficiency: Items can be moved much faster than by human couriers, especially in large buildings or between floors, streamlining operations and improving productivity.

Increased Accuracy: The system reduces the likelihood of items being misplaced or delivered to the wrong location, minimizing errors in financial transactions.

Superior Customer Service: In drive-through banking, pneumatic tubes allow for quick and convenient transactions without the need for face-to-face interaction, enhancing customer satisfaction and reducing wait times.

How Bank Tube Systems Operate

In a typical bank setup, pneumatic tubes might connect various critical areas:

- Teller stations to a central cash vault

- Drive-through lanes to teller stations inside the bank

- Different departments within a large bank building

Let's examine how a transaction might unfold at a drive-through bank:

A customer arrives at the drive-through lane and places their transaction materials (e.g., deposit slip and cash) into a carrier.

The carrier is inserted into the tube system, which rapidly transports it to a teller inside the bank.

The teller processes the transaction and places any necessary items (receipt, cash, etc.) back into the carrier.

The carrier is sent back through the tube system to the customer's lane.

The customer retrieves their items from the carrier, completing the transaction.

This entire process can typically be completed in a matter of minutes, significantly faster than if the customer had to park and enter the bank. The efficiency of this system not only improves customer satisfaction but also allows banks to serve more clients in less time, optimizing their operations.

The Rich History of Pneumatic Tube Transport

Early Developments

The concept of using air pressure to transport objects has a surprisingly long and fascinating history:

In the 1st century AD, Hero of Alexandria, a Greek mathematician and engineer, described a pneumatic system for opening temple doors, showcasing an early understanding of pneumatics.

In 1667, Denis Papin, a French physicist, proposed using pressurized air to transport packages over long distances, laying the theoretical groundwork for modern pneumatic systems.

However, it wasn't until the 19th century that practical pneumatic tube systems began to emerge and gain widespread use.

The Golden Age of Pneumatic Tubes

The late 19th and early 20th centuries saw a boom in pneumatic tube technology, with several landmark developments:

1853: The first operational pneumatic tube system was installed in London for telegraphs, marking the beginning of practical pneumatic transport.

1865: Paris introduced a citywide pneumatic mail system, demonstrating the scalability of the technology for urban applications.

1897: New York City launched an ambitious pneumatic mail system connecting 23 post offices, showcasing the potential for large-scale implementation.

During this period, some visionaries even proposed using large-scale pneumatic tubes for passenger transport, although these ideas remained in the realm of science fiction.

Modern Applications and Evolution

While many large-scale pneumatic mail systems were phased out by the mid-20th century due to the rise of electronic communication, the technology found new and diverse applications:

Hospitals began using pneumatic tubes to transport lab samples and medications, improving efficiency and patient care.

Banks, as we've discussed, adopted the technology for secure cash handling and customer service.

Large retail stores used pneumatic tubes to move cash from registers to a central office, enhancing security and streamlining operations.

Today, pneumatic tube systems continue to evolve, incorporating modern control systems, tracking technologies, and integration with other smart building systems.

The Future of Pneumatic Tube Technology

Despite their long history, pneumatic tube systems are far from obsolete. In fact, they continue to evolve and find new applications in our increasingly high-tech world.

Advanced Control Systems

Modern pneumatic tube systems often incorporate sophisticated control systems that can:

- Track the location of each carrier in real-time, providing unprecedented visibility into system operations.

- Optimize routing for maximum efficiency, reducing transit times and energy consumption.

- Provide detailed usage analytics, allowing organizations to fine-tune their operations.

- Interface with other building management systems for comprehensive facility control.

Integration with IoT and AI

The Internet of Things (IoT) and Artificial Intelligence (AI) are beginning to make significant inroads into pneumatic tube technology:

- IoT sensors can monitor system performance in real-time, predicting maintenance needs and preventing downtime.

- AI algorithms can optimize routing and scheduling in complex systems, adapting to changing usage patterns and demand.

These advancements are making pneumatic tube systems more efficient, reliable, and adaptable than ever before.

Emerging Applications

Innovative uses for pneumatic tube technology continue to emerge across various industries:

- Some cutting-edge restaurants are experimenting with pneumatic food delivery systems, bringing a futuristic flair to dining experiences.

- Certain manufacturing processes use pneumatic tubes to move small parts or materials with precision and speed.

- There's ongoing research into using large-scale pneumatic systems for waste management in smart cities, potentially revolutionizing urban sanitation.

The Hyperloop Concept: Pneumatic Tubes on a Grand Scale

Perhaps the most ambitious extrapolation of pneumatic tube technology is the Hyperloop concept, proposed by entrepreneur Elon Musk. This theoretical transportation system would use low-pressure tubes to transport passengers at extremely high speeds over long distances.

While the Hyperloop faces significant technical and practical challenges, it demonstrates that the core principles behind pneumatic tube transport continue to inspire innovative thinking and push the boundaries of what's possible in transportation technology.

Conclusion: The Enduring Legacy of Pneumatic Tube Systems

From their humble beginnings in the 19th century to their continued use in modern banks, hospitals, and beyond, pneumatic tube systems have proven to be a remarkably enduring and adaptable technology. By harnessing the simple yet powerful principle of air pressure, these systems provide a fast, secure, and efficient means of transporting physical items in an increasingly digital world.

As we've explored in this article, the science behind pneumatic tubes is both fascinating and accessible, relying on fundamental principles of physics that we encounter in our everyday lives. Whether you're making a deposit at a drive-through bank, receiving medication in a hospital, or perhaps one day traveling via Hyperloop, the influence of pneumatic tube technology is far-reaching and often underappreciated.

While digital technology continues to transform many aspects of our lives, the persistence and evolution of pneumatic tube systems remind us that sometimes, the most effective solutions are those that combine time-tested principles with modern innovations. As we look to the future, it's clear that pneumatic tube technology will continue to evolve, finding new applications and continuing to play a vital role in our increasingly connected world.

So the next time you encounter a pneumatic tube system, take a moment to appreciate the elegant simplicity and surprising complexity of this enduring technology. It stands as a testament to human ingenuity and a reminder that sometimes, the most effective solutions are hiding in plain sight – or perhaps, just behind the walls. In the realm of efficient, secure, and rapid physical transport, pneumatic tubes continue to prove that sometimes, the old ways are still the best ways – especially when enhanced by the latest technological advancements.