In an age where precision and reliability are paramount, thermocouples stand as unsung heroes in the realm of temperature measurement. These deceptively simple devices play a crucial role in countless applications, from ensuring the safety of jet engines to perfecting your morning cup of coffee. Let's embark on a journey to unravel the mysteries of thermocouples and discover how they quietly revolutionize our daily lives.

The Seebeck Effect: The Heart of Thermocouple Technology

At the core of every thermocouple lies a phenomenon discovered in 1821 by German physicist Thomas Johann Seebeck. This effect, aptly named the Seebeck effect, forms the foundation of thermoelectric technology. To understand how thermocouples work, we must first delve into this fundamental principle.

When two different metals are joined together and their junctions are exposed to different temperatures, a small electrical current is generated. This current flows through the circuit created by the two metals, and its magnitude is directly proportional to the temperature difference between the junctions. It's a beautiful dance of electrons, driven by the heat differential, that allows us to measure temperature with remarkable accuracy.

The Seebeck effect occurs because electrons in metals behave much like molecules in a gas. When heated, these electrons gain energy and move more rapidly. In a metal bar with one end hotter than the other, electrons at the hot end move faster, creating a net flow towards the cooler end. This migration of electrons results in a slight positive charge at the hot end and a negative charge at the cool end, establishing a voltage difference.

The Anatomy of a Thermocouple

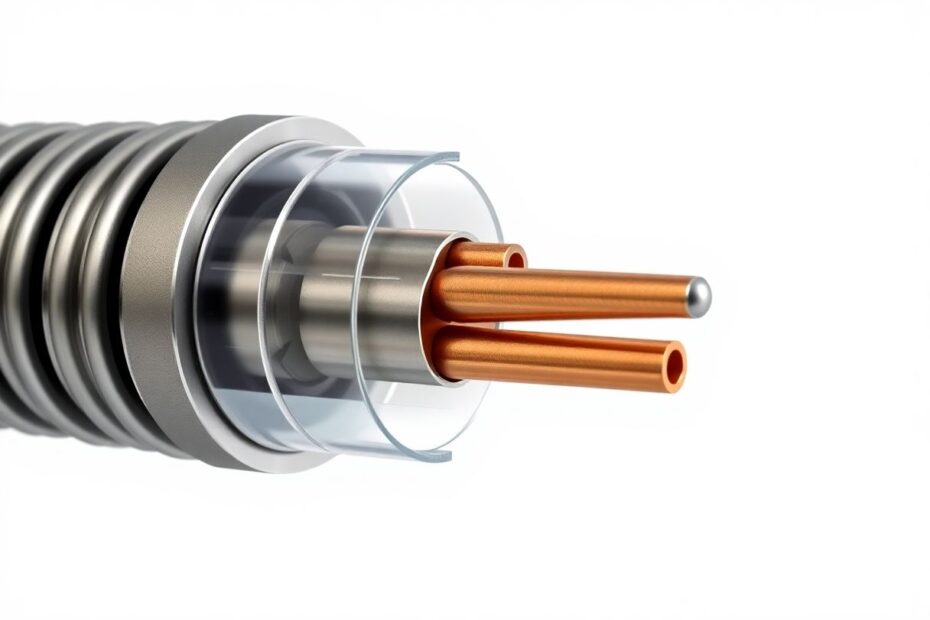

While the principle behind thermocouples is straightforward, their practical implementation involves careful engineering. A typical thermocouple consists of two different metal wires, often alloys, joined at one end to form what's called the measuring junction. The other ends of these wires, known as the reference junction, are connected to a voltage-measuring device.

To protect these delicate wire junctions from harsh environments, thermocouples are often encased in a metal sheath made of materials like stainless steel or nickel-chromium alloys. Inside this sheath, the wires are surrounded by a compacted mineral oxide insulation, ensuring electrical isolation and thermal conductivity. The entire assembly is then sealed with a specialized cement and covered with an outer layer of electrical insulation, usually rubber or plastic.

Types of Thermocouples: A Rainbow of Temperature Sensing

Thermocouples come in a variety of types, each designated by a letter according to international standards. The choice of metals used in a thermocouple determines its temperature range, accuracy, and suitability for different environments. Here's a brief overview of some common thermocouple types:

- Type K: The most common general-purpose thermocouple, using nickel-chromium and nickel-alumel alloys. It offers a wide temperature range from -200°C to +1350°C.

- Type J: Made from iron and constantan, suitable for reducing atmospheres and temperatures up to 760°C.

- Type T: Copper and constantan combination, excellent for low-temperature applications down to -250°C.

- Type E: Chromel and constantan, known for high sensitivity and good performance in oxidizing atmospheres.

- Type N: Nicrosil and nisil alloys, designed for improved stability at high temperatures up to 1300°C.

- Types R and S: Platinum-based thermocouples for high-temperature precision measurements up to 1768°C.

- Type B: Platinum-rhodium alloys for extreme high-temperature applications up to 1820°C.

The Science Behind Thermocouple Accuracy

Thermocouples are prized for their accuracy, but achieving precise measurements requires understanding several key factors. The voltage produced by a thermocouple is typically very small, often in the microvolt range. This necessitates the use of high-quality voltmeters or specialized thermocouple readout devices capable of measuring these minute signals accurately.

Another crucial aspect of thermocouple accuracy is cold junction compensation. The voltage generated by a thermocouple depends on the temperature difference between its measuring junction and reference junction. In practice, the reference junction is often at room temperature, which can fluctuate. To account for this, modern thermocouple systems use electronic cold junction compensation, typically employing a precise temperature sensor at the reference junction to correct for ambient temperature variations.

The relationship between temperature and voltage in a thermocouple is not perfectly linear, which can complicate measurements. To address this, thermocouple systems use lookup tables or complex polynomial equations to convert the measured voltage into an accurate temperature reading. These conversion methods are based on extensive calibration data collected for each thermocouple type.

Applications: From the Mundane to the Extreme

The versatility of thermocouples is truly remarkable, finding applications across a vast spectrum of industries and scientific endeavors. In the realm of everyday life, thermocouples ensure your oven maintains the right temperature for that perfect roast and help your car's engine run efficiently by monitoring coolant temperature.

In industry, thermocouples are workhorses in process control and safety systems. They monitor temperatures in steel mills, glass furnaces, and chemical reactors, ensuring product quality and preventing dangerous overheating. The food and beverage industry relies on thermocouples for everything from pasteurization to refrigeration, safeguarding our food supply.

Aerospace engineers depend on thermocouples to monitor the scorching temperatures inside jet engines, where precision is a matter of life and death. In space exploration, these sensors help manage the thermal environment of spacecraft, protecting delicate equipment and astronauts alike from the extreme temperature swings of outer space.

Scientists pushing the boundaries of knowledge also turn to thermocouples. In particle physics experiments, like those conducted at CERN's Large Hadron Collider, specialized thermocouples monitor temperatures in superconducting magnets cooled to near absolute zero. At the other extreme, volcanologists use rugged thermocouples to measure the blistering heat of lava flows, providing crucial data for eruption predictions.

The Future of Thermocouple Technology

While thermocouples might seem like a mature technology, innovation continues to push their capabilities further. Researchers are exploring new material combinations to extend temperature ranges and improve accuracy. For instance, graphene-based thermocouples show promise for ultra-high temperature measurements above 2000°C, potentially revolutionizing fields like aerospace and nuclear energy.

Miniaturization is another frontier, with scientists developing micro- and nano-scale thermocouples for applications in microelectronics and biomedical devices. These tiny sensors could enable precise temperature monitoring inside computer processors or even within living cells for medical diagnostics.

The integration of thermocouples with wireless technology and the Internet of Things (IoT) is opening new possibilities for remote temperature monitoring and predictive maintenance. Imagine a factory where hundreds of wireless thermocouples continuously report to a central system, allowing for real-time optimization of processes and early detection of equipment issues.

Conclusion: The Enduring Legacy of a Simple Principle

As we've explored the world of thermocouples, it's clear that these devices, based on a 200-year-old discovery, continue to play a vital role in our modern world. From ensuring our safety and comfort to enabling cutting-edge scientific research, thermocouples exemplify how a deep understanding of fundamental physical principles can lead to transformative technologies.

The next time you enjoy a perfectly brewed cup of coffee or board a flight, take a moment to appreciate the hidden thermocouples working tirelessly behind the scenes. These elegant sensors, born from the marriage of heat and electricity, remind us of the power of scientific discovery and the endless possibilities that arise when we harness the laws of nature for practical applications.

In a world increasingly driven by digital technologies, thermocouples stand as a testament to the enduring value of analog principles. They continue to evolve, adapt, and find new applications, proving that sometimes the simplest solutions are also the most powerful. As we face new challenges in energy, climate, and technology, the humble thermocouple will undoubtedly continue to play a crucial role in shaping our future.