Introduction: The Hidden Complexity in Everyday Sewing

At first glance, a sewing machine might seem like a simple device – it sews fabric together, after all. But beneath its unassuming exterior lies a marvel of engineering that has revolutionized the textile industry and home crafting for nearly two centuries. These clever machines employ a complex interplay of mechanisms to create neat, consistent stitches at speeds that would be impossible by hand. In this deep dive, we'll unravel the inner workings of sewing machines, exploring their fascinating history, key components, and the ingenious techniques they use to join fabrics with precision and efficiency.

The Fundamental Principle: Understanding the Lock Stitch

To truly appreciate how a sewing machine works, we must first grasp the key difference between machine sewing and hand sewing. When sewing by hand, one typically uses a single thread to create a running stitch, constantly reversing the direction of the needle. Sewing machines, however, employ a more sophisticated approach known as the lock stitch.

The lock stitch technique utilizes two separate threads: one fed from above by the needle, and another supplied from below by a bobbin. This dual-thread system is the cornerstone of how sewing machines function without tangling or unraveling. The interlocking of these two threads creates a strong, flexible seam that can withstand repeated wear and washing.

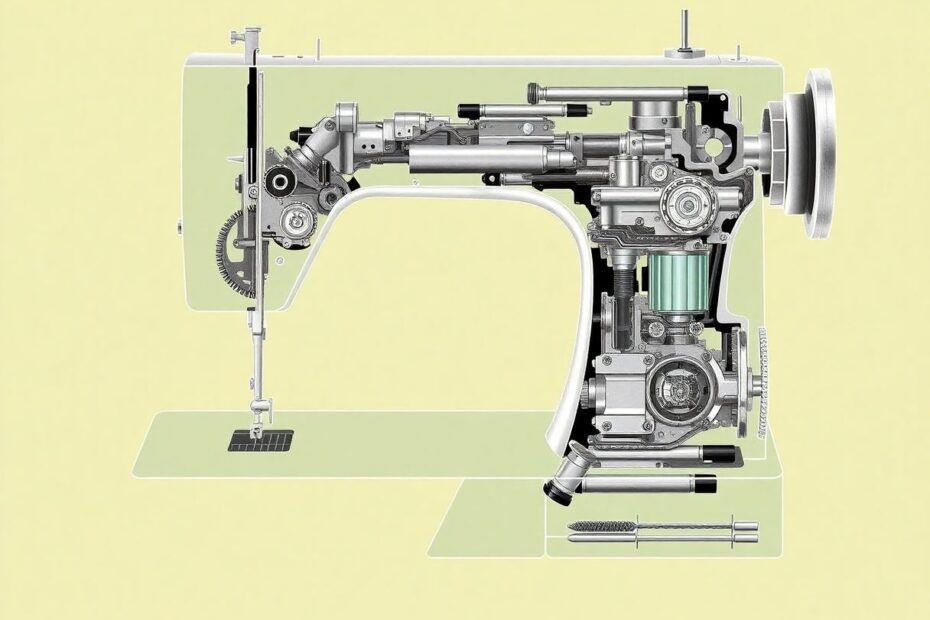

Anatomy of a Sewing Machine: Key Components

Before delving into the mechanics, it's essential to familiarize ourselves with the main parts of a typical sewing machine:

Electric Motor: The power source that drives all moving parts, converting electrical energy into mechanical motion.

Needle: A slender, pointed implement that pushes the top thread through the fabric. Modern needles are precision-engineered with specific shapes and sizes for different fabrics and tasks.

Presser Foot: A spring-loaded mechanism that holds the fabric firmly in place against the feed dogs, ensuring smooth movement and even stitching.

Feed Dogs: A set of metal teeth that move the fabric forward in precise increments between stitches, allowing for consistent stitch length.

Bobbin: A small spool that holds the bottom thread, typically housed within the machine's base.

Shuttle: A specially shaped device that houses the bobbin and plays a crucial role in forming stitches by interacting with the top thread.

Handwheel: Allows for manual control of the needle's position, useful for precise placement or troubleshooting.

Tension Dial: Adjusts the tightness of the upper thread, critical for achieving balanced stitches.

The Sewing Process: A Choreographed Dance of Threads

Now that we're familiar with the key players, let's walk through the intricate process of how a sewing machine creates a single stitch:

As the cycle begins, the needle, carrying the top thread, descends through the fabric. This motion is typically driven by a crankshaft connected to the motor, converting rotary motion into the reciprocating up-and-down movement of the needle.

As the needle reaches its lowest point and begins to rise, it leaves behind a small loop of thread below the fabric. This loop formation is critical to the lock stitch process.

At precisely the right moment, a rotating shuttle hook catches this loop. The timing of this interaction is crucial and represents one of the most ingenious aspects of sewing machine design.

The shuttle hook, rotating at high speed (often twice as fast as the needle's motion), pulls the top thread loop around the bobbin. The bobbin, nestled within the shuttle, supplies the bottom thread.

As the needle continues to rise, it tightens the loop, effectively "locking" the top and bottom threads together within the fabric layers.

Simultaneously, the feed dogs engage, moving the fabric forward slightly in preparation for the next stitch. This movement is typically driven by a series of cams and levers, translating the motor's rotation into the characteristic "walking" motion of the feed dogs.

This entire process repeats rapidly, often at speeds of 1000 stitches per minute or more in modern machines, creating a series of interlocked stitches that form a secure seam.

Engineering Marvels: The Mechanisms That Make It Possible

Several clever mechanisms work in concert to achieve this stitching process with remarkable precision:

Needle Mechanism: A crankshaft or cam system converts the motor's rotary motion into the needle's reciprocating motion. This often involves a series of gears or belts to achieve the necessary speed and force.

Bobbin and Shuttle Mechanism: The shuttle's rotation is precisely timed with the needle's motion, often achieved through a series of gears or a belt system. In many designs, the shuttle rotates twice for each complete cycle of the needle, ensuring proper loop capture.

Feed Dog Mechanism: A combination of cams, cranks, and linkages translates the motor's rotation into the complex motion of the feed dogs. This mechanism must raise the feed dogs above the needle plate, move them backward to engage the fabric, then lower and return them to their starting position – all in perfect synchronization with the needle's movement.

Tension Control: A spring-loaded system applies pressure to the upper thread, working in tandem with the lower bobbin tension to create balanced stitches. Many modern machines use electronically controlled solenoids for more precise tension adjustment.

The Evolution of Sewing Machines: From Wooden Wonders to Computerized Marvels

The history of sewing machines is a testament to human ingenuity and the iterative nature of technological progress:

1755: German inventor Charles Weisenthal patents a double-pointed needle for mechanical sewing, laying early groundwork for future innovations.

1830: French tailor Barthélemy Thimonnier builds one of the first practical wooden sewing machines, capable of creating a chain stitch.

1845: American inventor Elias Howe produces the first truly practical sewing machine using two threads and a curved needle – a design that would influence many future machines.

1851: Isaac Singer develops an affordable sewing machine and introduces the hire-purchase system, making machines accessible to a wider audience and revolutionizing home sewing.

1933: Singer introduces the Featherweight, the first truly portable sewing machine, weighing just 11 pounds. This opened up new possibilities for mobile sewing and increased the machine's versatility.

1978: The first computer-controlled sewing machine is announced, marking the beginning of the digital era in sewing technology.

Modern Innovations: Sewing in the Digital Age

Today's sewing machines often incorporate advanced electronics and microprocessors, allowing for features that would have seemed like science fiction to early inventors:

- Precise stitch selection and customization through digital interfaces

- Automated tension adjustment based on fabric type and stitch selection

- Programmable embroidery patterns with vast design libraries

- Touchscreen controls for intuitive operation

High-end machines push the boundaries even further with features like:

- Automatic thread cutting at the end of seams

- Sensor systems that detect fabric thickness and adjust settings accordingly

- Wi-Fi connectivity for downloading new patterns and updating firmware

- Built-in cameras for precise alignment and stitch placement

The Science of Thread Tension: Balancing Act for Perfect Stitches

Achieving proper thread tension is crucial for creating neat, strong stitches, and it represents a delicate balance of forces within the machine. The tension system typically consists of two main components:

Upper Tension: Controlled by a dial or electronic system, this applies pressure to the top thread as it feeds from the spool.

Lower Tension: A spring mechanism in the bobbin case provides resistance to the bottom thread.

When tension is perfectly balanced, the top and bottom threads interlock precisely in the middle of the fabric layers, creating stitches that appear identical on both sides. This balance is achieved when the force pulling on the top thread equals the force pulling on the bottom thread.

Tension issues can manifest in several ways:

- Loose upper thread results in visible loops on the bottom of the fabric

- Loose lower thread creates loops on the top of the fabric

- Extremely tight tension can cause puckering or breaking threads

Modern computerized machines often feature automatic tension adjustment, using sensors to detect thread type and fabric thickness. However, understanding the principles of tension remains crucial for troubleshooting and achieving optimal results in various sewing scenarios.

Specialized Stitches: Beyond the Basic Lock Stitch

While the lock stitch forms the foundation of machine sewing, modern machines offer a variety of specialized stitches, each with unique applications:

Zigzag Stitch: Used for finishing raw edges, sewing stretchy fabrics, and creating decorative effects. This stitch is achieved by the needle moving side-to-side as well as up-and-down.

Buttonhole Stitch: Creates reinforced holes for buttons, often in a single automated operation. This involves a complex sequence of straight and zigzag stitches.

Overlock Stitch: Finishes edges and joins fabrics in one operation, mimicking the function of a serger. This typically requires specialized feed mechanisms and multiple threads.

Decorative Stitches: Various patterns for embellishment, often involving complex needle movements and thread tensions.

These specialized stitches are achieved through variations in:

- Needle movement patterns, often controlled by cams or electronic systems

- Feed dog motion, which may involve differential feed for certain fabrics

- Tension adjustments, sometimes involving multiple tension discs

- Timing of thread release and uptake

The ability to perform these diverse stitches showcases the versatility and sophistication of modern sewing machine design.

Maintaining the Magic: Keeping Your Sewing Machine in Top Shape

Regular maintenance is key to ensuring your sewing machine continues to perform its intricate dance of threads and mechanisms:

Cleaning: Remove lint and debris, especially around the bobbin area and feed dogs. This prevents buildup that can interfere with smooth operation and stitch quality.

Oiling: Lubricate moving parts as recommended by the manufacturer. This reduces wear and ensures smooth, quiet operation. Modern machines often use self-lubricating bearings, but some parts may still require periodic oiling.

Needle Replacement: Change needles regularly, as worn or bent needles can damage fabric and affect stitch quality. Different fabrics may require specific needle types for optimal results.

Tension Checks: Periodically test and adjust thread tension, especially when switching between different types of thread or fabric.

Professional Servicing: Have the machine serviced by a qualified technician periodically. They can perform deep cleaning, timing adjustments, and other maintenance tasks that require specialized tools and expertise.

The Future of Sewing Machines: Innovation on the Horizon

As technology continues to advance, we're seeing exciting developments in sewing machine design:

AI-assisted sewing: Machines that can detect fabric type and automatically adjust settings for optimal stitching.

3D-printed components: Customizable parts for specialized sewing tasks, allowing for greater flexibility and personalization.

Eco-friendly models: Machines designed for energy efficiency and using sustainable materials, addressing growing environmental concerns.

Integration with smart home systems: Voice-controlled operations and remote monitoring, allowing seamless integration into connected homes.

Advanced materials: Development of new needle and thread materials to handle an ever-wider range of fabrics and applications.

Conclusion: The Enduring Legacy of a Clever Invention

The sewing machine stands as a testament to human ingenuity, combining mechanical precision with practical utility. From its humble beginnings to its modern computerized incarnations, it has transformed the way we produce textiles and clothing, democratizing fashion and empowering countless individuals to create and repair garments.

As we've explored, the core principle of the lock stitch remains at the heart of most sewing machines, a clever solution that has stood the test of time. The intricate dance of needle, thread, and shuttle continues to create the strong, flexible seams we rely on every day, now enhanced by digital precision and automated features.

Whether you're a professional seamstress, a hobby crafter, or simply curious about the technology around us, understanding how a sewing machine works offers a deeper appreciation for this ubiquitous yet often overlooked invention. It's a reminder that even in our high-tech world, some of the most impactful technologies are those that elegantly solve everyday problems.

The next time you hear the rhythmic hum of a sewing machine, take a moment to appreciate the dance of gears, cranks, and threads working in harmony to create something as simple and essential as a stitch. It's a small miracle of engineering that continues to shape our world, one seam at a time, bridging the gap between art and technology in the realm of textiles.