Gas boilers are the unsung heroes of modern home comfort, providing warmth and hot water with remarkable efficiency. As a science and technology enthusiast, I find the intricate mechanisms behind these ubiquitous appliances fascinating. In this comprehensive guide, we'll explore the inner workings of gas boilers, their components, and how they keep our homes cozy. Let's embark on a journey into the heart of gas central heating!

Understanding the Basics: What is a Gas Boiler?

At its core, a gas boiler is an ingenious appliance that harnesses the chemical energy stored in natural gas to heat water. This heated water is then circulated throughout your home, providing both central heating and hot water for taps and showers. Imagine a controlled furnace that efficiently converts the potential energy of gas molecules into thermal energy, all while maintaining safety and precision.

The process begins with the combustion of natural gas, typically methane (CH4). When methane reacts with oxygen in the air, it releases a significant amount of heat energy:

CH4 + 2O2 → CO2 + 2H2O + Heat

This chemical reaction is the foundation of how gas boilers operate, turning a simple hydrocarbon into the warmth that permeates our living spaces.

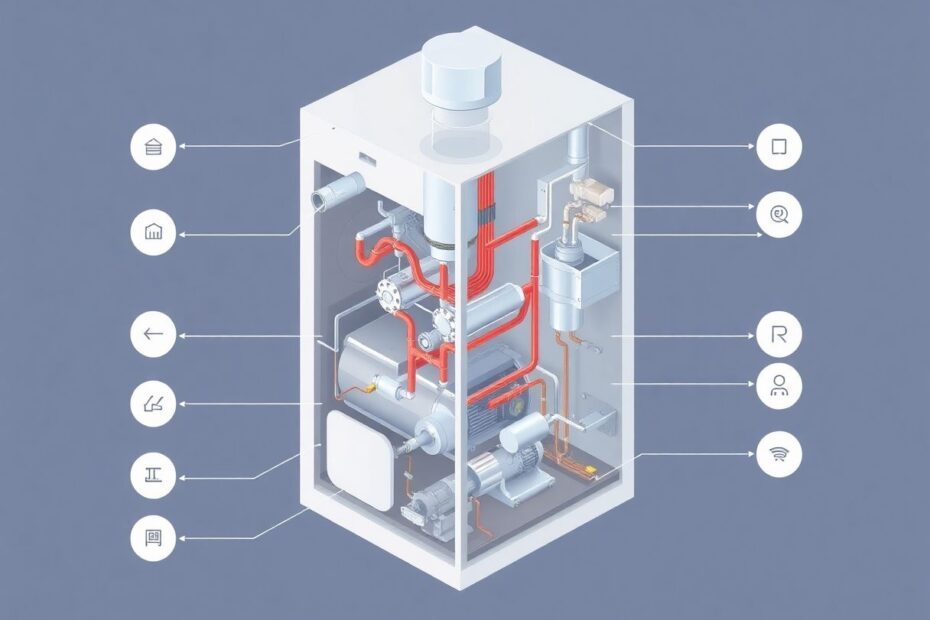

The Anatomy of a Gas Boiler: Key Components

Modern gas boilers are marvels of engineering, comprising several crucial components working in harmony. Let's examine each part and its role in the heating process:

Gas Valve and Burner

The gas valve is the gatekeeper, precisely controlling the flow of natural gas into the boiler. It's equipped with safety features to shut off gas supply in case of malfunctions. The burner is where the magic of combustion happens. It mixes gas with air in the perfect ratio (typically about 10 parts air to 1 part gas) to ensure efficient and complete combustion.

Heat Exchanger

The heat exchanger is the heart of the boiler. It's typically made of copper or stainless steel due to their excellent heat conductivity. As the hot combustion gases pass over the heat exchanger, thermal energy is transferred to the water circulating through it. The efficiency of this component is crucial to the overall performance of the boiler.

Circulating Pump

This electric pump is responsible for moving water through the boiler and the entire heating system. Modern pumps are often variable speed, adjusting their output to match the heating demand and improve energy efficiency.

Expansion Vessel

As water heats up, it expands. The expansion vessel, typically a metal container with a rubber diaphragm, accommodates this expansion, preventing excessive pressure buildup in the system.

Flue

The flue safely channels combustion gases out of your home. In condensing boilers, these gases are cooled to such an extent that water vapor condenses, releasing additional latent heat and improving efficiency.

Controls

The control system is the brain of the boiler, regulating its operation based on demand. It includes thermostats, timers, and often advanced algorithms for optimizing performance.

The Combustion Process: Where Science Meets Home Comfort

The combustion process in a gas boiler is a precisely controlled chain of events:

- Gas enters the boiler through the gas valve at a pressure of about 20 millibars (2 kPa).

- The gas mixes with air in the burner. This mixture is crucial: too little air results in incomplete combustion and carbon monoxide formation, while too much reduces efficiency.

- An electric spark or pilot light ignites the gas-air mixture, creating a controlled flame with temperatures reaching around 1,900°C (3,452°F).

- The flames heat the heat exchanger, which in turn heats the water passing through it. The water temperature typically rises to about 60-80°C (140-176°F).

- Heated water is pumped through the central heating system at a rate of about 15-20 liters per minute.

- Waste gases, mainly carbon dioxide and water vapor, are vented through the flue at temperatures of 150-200°C (302-392°F) in non-condensing boilers, or as low as 50-60°C (122-140°F) in condensing models.

Types of Gas Boilers: Choosing the Right System

Gas boilers come in three main types, each suited to different household needs:

Conventional Boilers

Also known as regular or open vent boilers, these systems require a separate hot water cylinder and cold water storage tank. They're ideal for homes with multiple bathrooms and high hot water demand. The hot water cylinder acts as a reservoir, storing heated water for use throughout the day.

System Boilers

System boilers are similar to conventional boilers but with many components built-in, eliminating the need for a cold water tank. They're more compact and easier to install, making them popular in modern homes. The hot water is still stored in a cylinder, providing a good balance between space-saving and high water demand capability.

Combi Boilers

Combination or 'combi' boilers are compact units that provide both heating and hot water on demand, without the need for separate tanks or cylinders. They heat water directly from the mains when you turn on a tap, ensuring a constant supply of hot water. Combi boilers are highly efficient and space-saving, making them the most popular choice for small to medium-sized homes in the UK.

The Efficiency Revolution: Condensing Boilers

Most modern gas boilers are condensing boilers, representing a significant leap in efficiency. Here's how they work:

Condensing boilers extract additional heat from waste gases that would otherwise be lost through the flue. As these gases cool below the dew point (around 55°C or 131°F), water vapor condenses, releasing latent heat. This process can make condensing boilers over 90% efficient, compared to 70-80% for non-condensing models.

The science behind this is fascinating. When water vapor condenses, it releases about 2,260 kJ/kg of latent heat. By capturing this energy, condensing boilers extract up to 11% more heat from the same amount of fuel compared to non-condensing models.

The resulting condensate is slightly acidic (pH around 3.5-5) due to dissolved carbon dioxide. It's safely drained away, typically neutralized by limestone chips in the drainage system before entering the sewers.

Home Central Heating: From Boiler to Radiator

Now that we understand the boiler, let's see how it fits into your home's heating system:

- The boiler heats water to around 60-80°C (140-176°F).

- An electric pump circulates this hot water through pipes to radiators throughout the house. The flow rate is typically 15-20 liters per minute.

- Radiators, essentially large metal heat exchangers, release heat into rooms. A typical radiator might emit about 1-2 kW of heat.

- As the water cools, it returns to the boiler to be reheated. The temperature drop is usually around 10-20°C.

- This cycle continues until the desired temperature is reached, as monitored by the thermostat.

The Role of Thermostats: Precision Control

Thermostats are the brains of your heating system, employing sophisticated control algorithms to maintain comfort while maximizing efficiency. Modern smart thermostats can learn your habits and adjust heating automatically, potentially saving up to 31% on heating bills according to a study by the Fraunhofer Institute for Building Physics.

Radiators: The Often Overlooked Heat Distributors

Radiators play a crucial role in distributing heat from your gas boiler. They operate on the principle of convection:

- Hot water from the boiler (typically 60-80°C) flows through the radiator.

- The large surface area of the radiator (often 1-2 m² for a standard panel radiator) transfers heat to the surrounding air.

- As air near the radiator warms, it rises, creating a convection current that efficiently distributes heat throughout the room.

- The cooled water (usually 10-20°C cooler) returns to the boiler to be reheated.

Thermostatic Radiator Valves (TRVs) offer an additional layer of control, allowing you to set different temperatures in different rooms. They can lead to energy savings of up to 30% according to a study by the Building Research Establishment.

Environmental Considerations and the Future of Home Heating

While modern gas boilers are efficient, they still contribute to carbon emissions. A typical household gas boiler emits about 2.75 tonnes of CO2 per year. As we move towards a more sustainable future, alternatives like heat pumps and hydrogen boilers are gaining traction.

Heat pumps can achieve efficiencies of 300-400%, extracting heat from the air or ground. Hydrogen boilers, which produce only water as a byproduct, are being developed as a potential drop-in replacement for natural gas boilers.

Conclusion: The Marvels of Modern Heating

Gas boilers are technological marvels that have revolutionized home comfort. From the controlled combustion of gas to the efficient distribution of heat throughout your home, these systems represent the culmination of centuries of scientific and engineering progress.

As we've explored, the principles of thermodynamics, fluid dynamics, and chemistry all come together in these compact units. Whether you're enjoying a warm shower or cozying up on a winter evening, remember the intricate dance of molecules and energy happening behind the scenes.

Understanding how our heating systems work empowers us to use them more efficiently and make informed decisions about future upgrades. As we move towards a more sustainable future, the evolution of home heating technology continues, promising even greater efficiency and reduced environmental impact.

The next time you adjust your thermostat, take a moment to appreciate the engineering marvel that is your gas boiler – truly the unsung hero of home comfort.