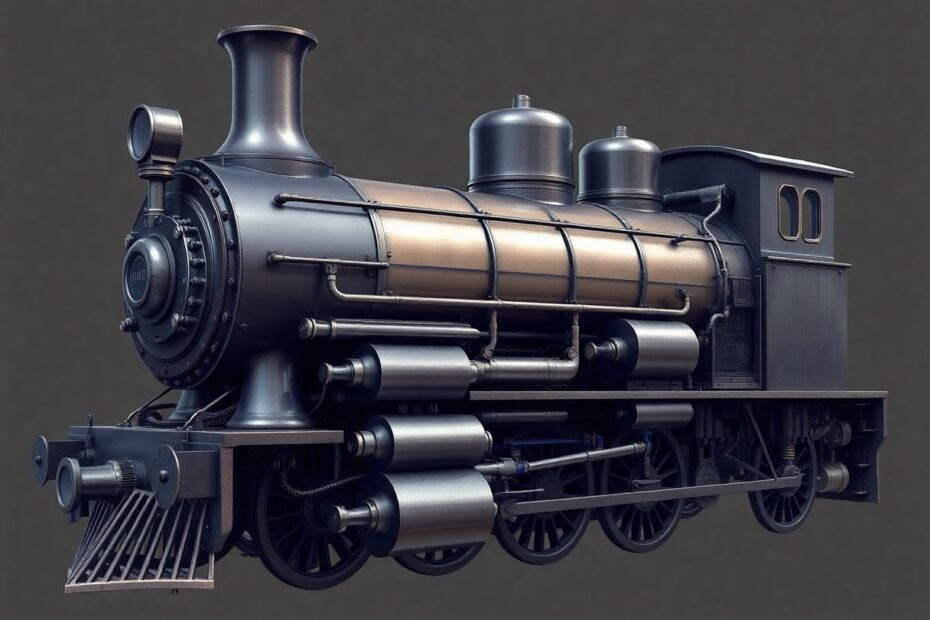

Steam engines, the marvels of engineering that revolutionized transportation and industry in the 18th and 19th centuries, continue to captivate our imagination. Though largely supplanted by more modern technologies, understanding the intricate workings of steam engines provides fascinating insights into the history of technology and the fundamental principles of thermodynamics. Let's embark on a journey to explore the inner workings of these mechanical wonders that shaped our world.

The Fundamental Principle: Harnessing Steam's Expansive Force

At its core, a steam engine converts the heat energy from burning fuel into mechanical energy. This seemingly simple concept belies the complexity and ingenuity behind these machines. The basic process involves heating water to create high-pressure steam, which then expands to drive a piston within a cylinder. This motion is then converted into rotary movement, powering everything from locomotives to factory machinery.

The Boiler: The Heart of the Steam Engine

The boiler serves as the powerhouse of the steam engine, where the transformation from heat energy to mechanical energy begins. Typically, coal burned in the firebox generates intense heat, which passes through a network of metal tubes immersed in water. This design maximizes heat transfer efficiency, rapidly converting water into steam.

Early boiler designs were relatively simple, but as engineers sought greater efficiency, they developed more sophisticated systems. The fire-tube boiler, patented by George Stephenson in 1829, became a standard in locomotive design. These boilers could contain upwards of 200 tubes, dramatically increasing the surface area for heat transfer and allowing for more rapid steam generation.

Water quality was crucial for boiler operation. Impurities could lead to scale buildup, reducing efficiency and potentially causing dangerous boiler explosions. To combat this, engineers developed systems for water treatment and regular boiler cleaning, showcasing how even seemingly minor details played a significant role in steam engine operation and safety.

Building Pressure: The Steam Dome and Pressure Management

As steam accumulates in the boiler, it collects in the steam dome. This component plays a critical role in ensuring only dry steam enters the engine's working parts. Wet steam, containing water droplets, could cause damage to the cylinders and reduce efficiency.

The pressure within a typical locomotive boiler could reach astounding levels, often between 200-300 psi (pounds per square inch). To put this in perspective, that's about 13-20 times the pressure in an average car tire. Managing this pressure was crucial for both efficiency and safety.

Boilers were equipped with multiple safety valves to prevent over-pressurization. These valves would automatically release excess steam if the pressure became too high. The iconic "choo-choo" sound associated with steam locomotives was actually the sound of these safety valves releasing steam!

The Valve System: Precision Timing for Maximum Power

The intricate valve system of a steam engine is a testament to the ingenuity of 19th-century engineers. This system controls the flow of steam into and out of the cylinders with precise timing, crucial for efficient operation.

The main regulator valve, typically located in the steam dome, controls the overall flow of steam from the boiler to the cylinders. From there, slide valves or piston valves at each cylinder manage the admission and exhaust of steam.

The development of various valve gear systems over the years showcases the continuous innovation in steam engine design. The Stephenson valve gear, invented in 1841, allowed for variable cutoff – the point at which steam admission to the cylinder is stopped, allowing the steam to expand for the remainder of the stroke. This significantly improved efficiency.

Later developments like the Walschaerts valve gear (1844) and the Baker valve gear (1903) offered improvements in maintenance ease and smoothness of operation. The fact that engineers were still refining steam engine design well into the 20th century demonstrates the long-lasting impact and continuing evolution of this technology.

Where the Magic Happens: Cylinders and Pistons

The cylinders are where steam power is converted into motion. As high-pressure steam enters one end of the cylinder, it pushes the piston to the other end. The valve system then switches, allowing steam to enter the opposite end while exhausting the used steam.

This reciprocating motion is the heart of the steam engine's power. In a typical locomotive, cylinders could range from 12 to 30 inches in diameter, with a stroke (the distance the piston travels) of up to 32 inches. The size and number of cylinders varied based on the engine's intended use and power requirements.

An interesting development in cylinder design was the use of compound engines. These engines used the steam multiple times, passing it through cylinders of increasing size. This extracted more work from the steam, significantly improving efficiency. The most advanced designs, like the triple-expansion engine, could achieve thermal efficiencies of up to 17%, a major improvement over early engines which were often less than 5% efficient.

From Reciprocation to Rotation: Connecting Rods and Crankshafts

The conversion of the piston's back-and-forth motion into rotary motion is accomplished through a system of connecting rods and crankshafts. This seemingly simple mechanism is a marvel of engineering, translating linear force into rotational force with remarkable efficiency.

In a locomotive, this system is duplicated on both sides of the engine, with the cranks set at 90-degree angles to each other. This ensures that there's always power being applied, even when one piston is at the end of its stroke, resulting in smoother operation and more consistent power delivery.

The size and design of these components were critical. For example, the connecting rods in a large locomotive could be over 10 feet long and weigh several hundred pounds. These massive components had to withstand enormous stresses while operating at high speeds, sometimes for hours on end.

Efficiency Improvements: The Quest for Better Performance

Early steam engines were notoriously inefficient, wasting up to 90% of the energy from the coal they burned. This inefficiency drove continuous innovation as engineers sought to extract more work from each pound of coal.

One significant improvement was the use of expanding steam. Instead of simply venting the steam after each stroke, engineers designed systems to allow the steam to expand in the cylinder before release, extracting more work from each admission of steam.

Another major advancement was the introduction of superheating. By heating the steam beyond its boiling point before it entered the cylinders, engineers could increase the engine's power and efficiency. Superheaters could raise steam temperatures to over 700°F (371°C), significantly boosting the engine's performance.

These improvements, combined with better metallurgy and manufacturing techniques, led to remarkable increases in efficiency. By the early 20th century, the most advanced steam locomotives could achieve thermal efficiencies of around 20%, a vast improvement over their early counterparts.

Beyond the Rails: Stationary Steam Engines

While steam locomotives capture much of the public imagination, stationary steam engines were the true workhorses of the Industrial Revolution. These engines powered factories, mines, and mills, driving the economic transformation of the 18th and 19th centuries.

Stationary engines often used different designs from their mobile counterparts. Beam engines, with their distinctive rocking beams, were common in the early days of the Industrial Revolution. These could be enormous – the largest beam engine ever built, the Cruquius engine in the Netherlands, had a cylinder 144 inches (3.66 m) in diameter and could pump 320 tons of water per minute.

Later designs like the Corliss engine, patented in 1849, featured precise valve timing that allowed for smooth, efficient operation. These engines were so reliable that some remained in service for over 100 years. The efficiency and reliability of stationary steam engines were crucial factors in the rapid industrialization of the 19th century.

The Enduring Legacy of Steam Power

Though largely replaced by internal combustion engines and electric motors in many applications, the legacy of steam power lives on. Most electricity today is still generated using steam turbines, albeit with the steam typically heated by nuclear reactions or the burning of fossil fuels.

Steam turbines, a more advanced application of steam power, are still widely used in marine propulsion for large ships. These turbines can generate enormous power – the turbines in a modern nuclear aircraft carrier can produce over 250,000 horsepower!

In industry, steam remains a crucial medium for heat transfer and is used in countless manufacturing processes. The principles of thermodynamics and energy conversion that were first widely applied in steam engines continue to underpin much of our modern technology.

Conclusion: The Steam Engine's Impact on Science and Society

The steam engine represents far more than just an interesting historical artifact. It was a transformative technology that reshaped the world, driving the Industrial Revolution and laying the foundation for our modern technological society.

Understanding how a steam engine works provides insights into fundamental principles of physics and engineering that remain relevant today. The challenges faced by steam engine designers – improving efficiency, managing high pressures and temperatures, converting between different types of motion – are still encountered in many fields of engineering.

Moreover, the story of the steam engine's development is a testament to human ingenuity and the power of incremental innovation. From Newcomen's early atmospheric engine to the highly efficient locomotives of the 20th century, each improvement built upon previous knowledge, driving progress forward.

As we face new energy challenges in the 21st century, the story of how we mastered steam power can serve as both inspiration and instruction. It reminds us of the transformative power of technological innovation and the importance of continuous improvement. The steam engine may be a technology of the past, but the principles it embodies and the lessons it teaches remain vitally relevant as we work to build a sustainable energy future.