In the palm of your hand lies more computing power than filled entire rooms in the 1940s. This technological miracle is made possible by integrated circuits (ICs), the microscopic marvels that have revolutionized our world. Let's embark on a journey to understand how these tiny technological wonders work, trace their fascinating history, and explore their profound impact on modern technology.

The Essence of Integrated Circuits

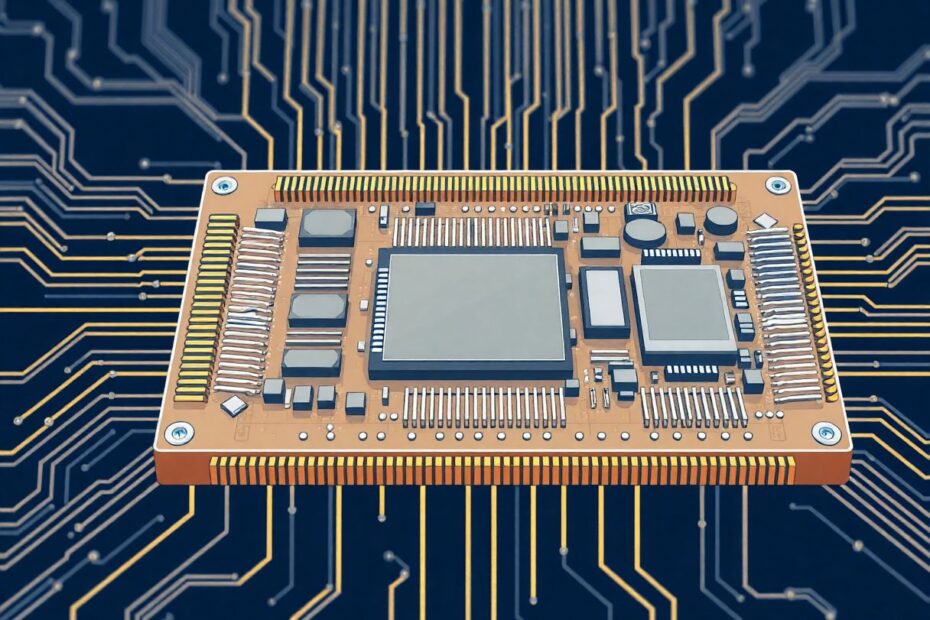

An integrated circuit, often referred to as a microchip or simply a chip, is a complete electronic circuit miniaturized and manufactured on a single piece of semiconductor material, typically silicon. These diminutive devices can contain anywhere from a few dozen to billions of electronic components, all working in harmony to perform specific functions.

To truly appreciate the significance of integrated circuits, we must first understand their historical context. In the 1940s, the ENIAC, one of the first electronic computers, utilized a staggering 18,000 vacuum tubes and occupied a space equivalent to a large room. The invention of the transistor in 1947 marked a significant step forward, offering a smaller and more reliable alternative to vacuum tubes. However, it was the creation of the integrated circuit in 1958 that truly paved the way for the miniaturization revolution we've witnessed over the past six decades.

The Advantages of Integrated Circuits

Integrated circuits offer a multitude of benefits over traditional electronic circuits, making them the cornerstone of modern electronics:

Size reduction is perhaps the most obvious advantage. ICs are dramatically smaller than circuits built with discrete components, allowing for the creation of increasingly compact devices. This miniaturization has enabled the development of technologies we now take for granted, such as smartphones and wearable devices.

Speed is another crucial factor. The shorter distances between components in an IC allow for faster operation, significantly boosting processing power. This increased speed has been instrumental in the development of high-performance computing systems and real-time applications.

Power efficiency is a key benefit of ICs. They require less energy to run compared to their discrete counterparts, leading to longer battery life in portable devices and reduced energy consumption in larger systems. This efficiency has been pivotal in the development of mobile technologies and in reducing the environmental impact of electronics.

Reliability is greatly enhanced in integrated circuits. Fewer connections between components mean fewer potential points of failure, resulting in more robust and long-lasting electronic devices. This reliability has been crucial in applications ranging from consumer electronics to critical systems in aerospace and medicine.

Cost-effectiveness is another significant advantage. While the initial development of an IC can be expensive, mass production makes them relatively inexpensive on a per-unit basis. This economy of scale has been instrumental in making advanced technology accessible to a wider audience.

The Intricate Process of IC Fabrication

The creation of an integrated circuit is a marvel of modern engineering, combining principles from physics, chemistry, and precision manufacturing. Let's delve deeper into this fascinating process:

1. The Silicon Foundation

The journey begins with silicon, the second most abundant element in the Earth's crust. Silicon is a semiconductor, meaning its electrical conductivity can be manipulated to either conduct or insulate electricity. This unique property makes it the ideal material for creating the building blocks of integrated circuits.

2. Wafer Creation

The process starts with the growth of a large, pure silicon crystal in the shape of a cylinder. This crystal is then precisely sliced into thin discs called wafers, each about the thickness of a credit card. These wafers serve as the foundation upon which the intricate circuitry will be built.

3. Circuit Design

Before any physical manufacturing begins, engineers meticulously design the circuit using specialized computer-aided design (CAD) software. This design serves as the blueprint for the physical chip, detailing the layout of every transistor, resistor, and capacitor that will be created on the silicon wafer.

4. Photolithography: Printing the Circuit

The heart of the IC manufacturing process is photolithography, a technique similar to developing a photograph but on a microscopic scale. The silicon wafer is first coated with a light-sensitive material called photoresist. A mask containing the circuit pattern is then placed over the wafer, and the assembly is exposed to ultraviolet light. This light hardens the exposed photoresist, while the unexposed areas remain soft and are subsequently washed away, leaving a pattern on the wafer that corresponds to the circuit design.

5. Etching and Doping

The exposed areas of silicon are then etched away using either chemicals or plasma, creating the basic structure of the circuit. Following this, the chip undergoes a process called doping, where impurities like boron or phosphorus are introduced to create areas with different electrical properties. This step is crucial in forming the various components of the circuit, such as transistors and diodes.

6. Building Layers

The photolithography, etching, and doping processes are repeated many times, building up multiple layers of the circuit. Metal connections are added to link different parts of the circuit, creating a three-dimensional network of electronic components. Modern high-performance chips can have dozens of layers, each adding to the functionality and complexity of the final product.

7. Testing and Packaging

Once the layering process is complete, each chip on the wafer is rigorously tested for functionality. The wafer is then cut into individual chips, and those that pass the testing phase are packaged in protective casings with pins for connecting to other components. This final step prepares the integrated circuits for integration into electronic devices.

The Science Behind Integrated Circuits

To truly understand how integrated circuits work, we need to explore the fascinating world of semiconductor physics. At the heart of every IC lies the manipulation of electrical charges within silicon, achieved through a process called doping.

Doping involves intentionally introducing impurities into the silicon to alter its electrical properties. There are two types of doping:

N-type doping: This process involves adding elements like phosphorus or arsenic, which have more valence electrons than silicon. This introduces extra electrons into the silicon lattice, creating a negative charge carrier.

P-type doping: In this case, elements like boron, which have fewer valence electrons than silicon, are added. This creates "holes" or areas lacking electrons, which act as positive charge carriers.

By strategically combining areas of n-type and p-type silicon, engineers can create various electronic components within the integrated circuit:

- Diodes are formed at the junction of n-type and p-type silicon, allowing current to flow in only one direction.

- Transistors, the building blocks of digital logic, are created by sandwiching one type of silicon between two layers of the other type (e.g., n-p-n or p-n-p).

- Capacitors, which store electrical charge, are formed using insulating layers between conductive plates.

- Resistors, which control current flow, are created using specific patterns of doped silicon.

The Evolution and Future of Integrated Circuits

The history of integrated circuits is a testament to human ingenuity and the relentless pursuit of technological advancement. In 1965, Gordon Moore, co-founder of Intel, made a prescient observation that would come to be known as Moore's Law: the number of transistors on a chip was doubling approximately every two years. This prediction has held remarkably true for decades and has driven the rapid advancement of computing power.

To put this evolution into perspective, consider these milestones:

- 1971: The first commercial microprocessor, the Intel 4004, contained 2,300 transistors.

- 1981: The IBM PC's Intel 8088 processor had 29,000 transistors.

- 2000: Intel's Pentium 4 boasted 42 million transistors.

- 2022: Apple's M1 Ultra chip contains a staggering 114 billion transistors.

As we approach the physical limits of silicon-based technology, researchers are exploring new frontiers to continue this trajectory of advancement:

- Quantum computing harnesses the principles of quantum mechanics to achieve unprecedented computing power for certain types of problems.

- 3D chip stacking increases density by building upwards, allowing for more components in the same footprint.

- New materials like graphene or carbon nanotubes are being explored as alternatives to silicon, potentially offering better performance and efficiency.

- Neuromorphic computing aims to design chips that mimic the structure and function of the human brain, potentially revolutionizing artificial intelligence and machine learning applications.

The Ubiquitous Impact of Integrated Circuits

The impact of integrated circuits on modern life cannot be overstated. They have transformed virtually every aspect of our world:

In computing, ICs have enabled the development of devices ranging from supercomputers capable of modeling complex systems to smartwatches that monitor our health in real-time.

The field of communications has been revolutionized by integrated circuits. Smartphones, satellites, and the entire internet infrastructure rely on these tiny marvels to process and transmit vast amounts of data across the globe.

Transportation has been significantly enhanced by ICs. Modern vehicles contain dozens of microchips controlling everything from engine management systems to GPS navigation. The development of autonomous vehicles would be impossible without the advanced processing capabilities provided by integrated circuits.

In medicine, integrated circuits have enabled the creation of sophisticated diagnostic tools like MRI machines, as well as life-saving devices such as pacemakers and hearing aids. The miniaturization of these components has allowed for less invasive medical procedures and more effective treatments.

The entertainment industry has been transformed by ICs. High-definition televisions, gaming consoles, and digital cameras all rely on integrated circuits to process and display immersive audiovisual experiences.

In industry, integrated circuits power robotics, automation systems, and Internet of Things (IoT) devices, increasing efficiency and enabling new forms of manufacturing and data collection.

Conclusion: The Unsung Heroes of the Digital Age

Integrated circuits have come a long way since their invention in the late 1950s. These tiny marvels of engineering have transformed our world, enabling the digital revolution and powering the devices we rely on every day. From the smartphone in your pocket to the satellites orbiting Earth, integrated circuits are the unsung heroes of our technological age, working tirelessly behind the scenes to make our modern world possible.

As we continue to push the boundaries of what's possible with ICs, we can only imagine the innovations that lie ahead. The future promises even more powerful, efficient, and versatile integrated circuits that will continue to shape our world in ways we can scarcely imagine. The story of integrated circuits is far from over; it is a testament to human ingenuity and a beacon of hope for future technological breakthroughs that will address some of humanity's greatest challenges.