Heat engines are marvels of engineering that have shaped the modern world. From the roaring engines of sports cars to the massive turbines powering electrical grids, these devices harness thermal energy to produce the mechanical work that drives our technological society. But how exactly do heat engines accomplish this remarkable feat? Let's dive into the fascinating world of thermodynamics and engineering to uncover the inner workings of these powerful machines.

The Fundamental Concept: Harnessing Temperature Differences

At its core, a heat engine operates on a beautifully simple principle: it converts thermal energy (heat) into mechanical energy (work) by exploiting temperature differences. This concept, first articulated by the brilliant French physicist Nicolas Sadi Carnot in the 1820s, forms the foundation of all heat engine designs.

Carnot recognized that the key to a heat engine's operation lies in the transfer of heat from a high-temperature source to a low-temperature sink. The greater this temperature difference, the more potential work the engine can produce. This insight led to the development of the Carnot cycle, an idealized thermodynamic cycle that represents the maximum theoretical efficiency achievable by any heat engine operating between two specific temperatures.

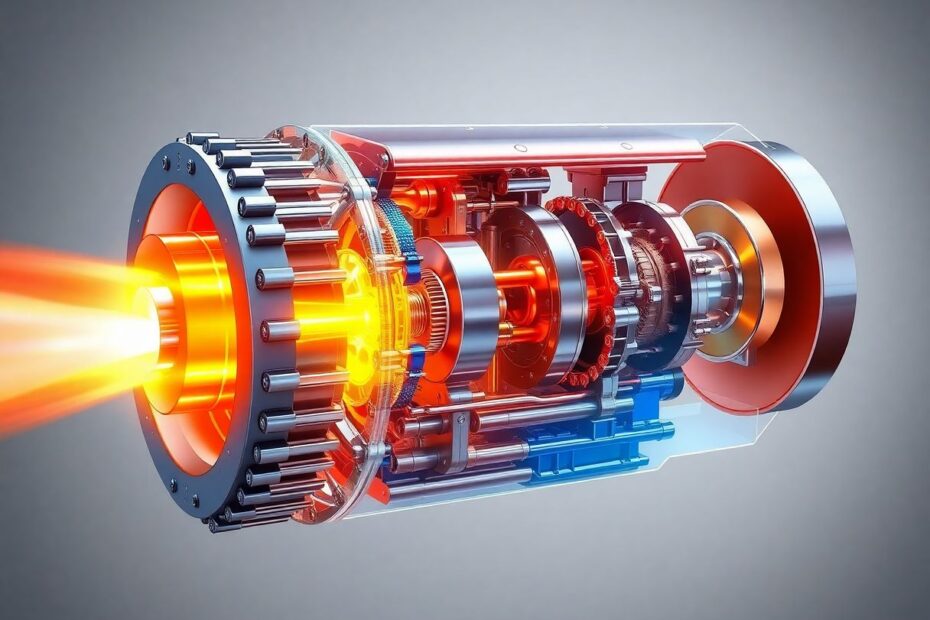

The Anatomy of a Heat Engine

While heat engines come in many forms, they all share some common components:

A heat source: This provides the high-temperature thermal energy, often through combustion of fuel or absorption of solar radiation.

A working substance: This material (typically a gas or liquid) expands when heated and contracts when cooled, converting thermal energy into mechanical motion.

A mechanism for converting expansion into useful work: This could be a piston, turbine, or other device that harnesses the working substance's motion.

A heat sink: This lower-temperature reservoir allows the working substance to cool and complete its cycle.

A means of returning the working substance to its initial state: This ensures the engine can operate continuously.

Types of Heat Engines: External vs. Internal Combustion

Heat engines can be broadly categorized into two main types: external combustion engines and internal combustion engines.

External Combustion Engines

In external combustion engines, the fuel is burned outside the engine's main power-producing component. The most famous example is the steam engine, which played a pivotal role in the Industrial Revolution. Here's how a typical steam engine operates:

- Fuel (often coal) is burned in a furnace, heating water in a boiler to produce high-pressure steam.

- The steam is directed into a cylinder, where it expands and pushes a piston.

- The piston's motion is converted to rotary motion via a connecting rod and crankshaft.

- The spent steam is exhausted or condensed for reuse, and the cycle repeats.

Other examples of external combustion engines include Stirling engines and some types of nuclear power plants. These engines often have the advantage of being able to use a wide variety of fuel sources, as the combustion process is separate from the working fluid.

Internal Combustion Engines

Internal combustion engines, on the other hand, burn fuel directly within the engine's power-producing component, typically a cylinder. The most common examples are gasoline and diesel engines found in most vehicles. Let's examine how a four-stroke gasoline engine works:

- Intake stroke: The piston moves down, drawing a mixture of fuel and air into the cylinder.

- Compression stroke: The piston moves up, compressing the fuel-air mixture.

- Power stroke: A spark ignites the compressed mixture, causing an explosion that drives the piston down.

- Exhaust stroke: The piston moves up, expelling the combustion products.

This cycle repeats rapidly, typically thousands of times per minute in a modern automobile engine. Diesel engines operate on a similar principle but use higher compression ratios to ignite the fuel without a spark.

The Quest for Efficiency: Thermodynamics in Action

The efficiency of a heat engine is a crucial metric, defined as the ratio of useful work output to heat input. Mathematically, it's expressed as:

Efficiency = (Work Output) / (Heat Input)

In terms of temperatures, the maximum theoretical efficiency (known as the Carnot efficiency) is given by:

Efficiency = (Thot – Tcold) / Thot

Where Thot is the absolute temperature of the hot reservoir and Tcold is the absolute temperature of the cold reservoir.

This formula reveals a fundamental truth about heat engines: their efficiency is limited by the temperature difference between the hot and cold reservoirs. The greater this difference, the higher the potential efficiency. This is why modern power plants strive to operate at extremely high temperatures, often exceeding 1000°C in the combustion chamber, while using cooling towers or large bodies of water as cold reservoirs.

Real-world heat engines, of course, never achieve the Carnot efficiency due to various losses and irreversibilities. For example, a typical gasoline automobile engine operates at around 20-35% efficiency, while large-scale combined cycle gas turbines can achieve efficiencies of up to 60%.

Innovations in Heat Engine Technology

Engineers and scientists continually strive to improve heat engine efficiency through various strategies:

Increasing operating temperatures: Materials science advances allow engines to withstand higher temperatures, increasing potential efficiency.

Reducing friction and other losses: Improved lubricants, better machining techniques, and advanced bearing designs minimize energy lost to friction.

Utilizing waste heat: Technologies like cogeneration and combined heat and power (CHP) systems capture and use heat that would otherwise be wasted.

Advanced combustion techniques: Innovations like homogeneous charge compression ignition (HCCI) and low-temperature combustion aim to burn fuel more efficiently and cleanly.

Hybrid systems: Combining different types of engines or energy sources can lead to improved overall efficiency, as seen in hybrid electric vehicles.

The Future of Heat Engines

Despite being centuries-old technology, heat engines continue to evolve and find new applications. Some exciting developments include:

Micro heat engines: Researchers are developing tiny heat engines at the microscale or even nanoscale, which could power small devices or sensors.

Thermoelectric generators: These solid-state devices directly convert heat to electricity without moving parts, offering potential for waste heat recovery in various applications.

Advanced materials: New materials like ceramic matrix composites allow for higher operating temperatures and improved efficiency in gas turbines.

Alternative cycles: Researchers are exploring variations on traditional thermodynamic cycles, such as the supercritical CO2 cycle, which could offer improved efficiency in certain applications.

Conclusion: The Enduring Impact of Heat Engines

Heat engines have been a cornerstone of technological progress since the Industrial Revolution, and their importance shows no signs of waning. From powering our vehicles to generating the majority of the world's electricity, these devices play a crucial role in our energy landscape.

Understanding how heat engines work – converting thermal energy into mechanical work through the clever manipulation of temperature differences – gives us a deeper appreciation for the machines that surround us. It also highlights the ongoing challenges and opportunities in energy efficiency and sustainable power generation.

As we face the pressing need to reduce carbon emissions and transition to more sustainable energy sources, heat engines will continue to play a vital role. Whether it's through incremental improvements in traditional engines or revolutionary new designs, the quest for more efficient ways to harness the power of heat goes on. The principles discovered by pioneers like Sadi Carnot continue to guide us, reminding us that in the dance between heat and work, there's always room for innovation.

The story of heat engines is far from over. As we push the boundaries of materials science, nanotechnology, and our understanding of thermodynamics, who knows what new marvels of engineering might emerge? One thing is certain: the fascinating interplay between heat and motion will continue to drive technological progress far into the future.