Concrete has been a cornerstone of human construction for millennia, but it's the development of reinforced concrete that truly revolutionized our ability to build taller, stronger, and more durable structures. This remarkable composite material has shaped our modern world in ways both visible and hidden, from soaring skyscrapers to resilient infrastructure. In this article, we'll explore the fascinating world of reinforced concrete, delving into its composition, benefits, applications, and the cutting-edge innovations that are propelling it into the future.

The Foundation of Modern Construction

Understanding Concrete: The Artificial Stone

At its core, concrete is an artificial stone, a mixture of carefully proportioned ingredients that come together to form a material of immense strength and versatility. The basic recipe for concrete includes:

- Aggregates (60-75%): This includes sand, gravel, and crushed stone, providing bulk and strength.

- Cement (10-15%): Usually Portland cement, which acts as the crucial binder.

- Water (15-20%): Activates the cement and allows the mixture to flow.

When these components are combined, a chemical reaction called hydration begins. Cement particles react with water, forming crystals that grow and interlock, binding the aggregates together. This process continues for years, with concrete gaining strength over time. In fact, research has shown that some Roman concrete structures are still gaining strength after 2,000 years, thanks to ongoing mineral formation within the material.

The Strength and Weakness Paradox

Concrete's greatest strength lies in its ability to resist compression. It can withstand enormous amounts of weight pressing down on it, which is why it's so commonly used in foundations, walls, and columns. According to the Portland Cement Association, high-strength concrete can resist compressive forces of up to 100 MPa (14,500 psi) or more.

However, concrete has a significant weakness: it's relatively poor at handling tensile forces (stretching or bending). Its tensile strength is typically only about 10-15% of its compressive strength. This limitation is where the ingenuity of reinforced concrete comes into play.

Reinforced Concrete: A Synergistic Solution

The Birth of a Revolution

The concept of reinforced concrete is brilliantly simple: embed steel bars or mesh within the concrete before it sets. This idea, first patented by Joseph Monier in 1867, created a composite material that combines the best properties of both concrete and steel:

- Concrete provides excellent compression resistance

- Steel provides excellent tension resistance

It's like giving concrete a skeleton, allowing it to resist bending and stretching forces that would crack plain concrete. This synergy between materials has enabled the construction of structures that were previously unimaginable.

The Science of Strength

The effectiveness of reinforced concrete relies on several key factors:

Bond strength: The concrete must grip the steel tightly to transfer forces between them. This is achieved through chemical adhesion, friction, and mechanical interlocking between the concrete and the ribbed surface of reinforcing bars.

Thermal compatibility: Concrete and steel expand and contract at similar rates (concrete: 10 × 10^-6 m/m/°C, steel: 11.7 × 10^-6 m/m/°C), preventing internal stresses that could lead to cracking or separation.

Corrosion protection: The alkaline nature of concrete (pH typically between 12.5 and 13.5) helps protect the steel from rusting by forming a passive oxide layer on the steel surface.

Types of Reinforcement

While steel rebar (reinforcing bars) is the most common type of reinforcement, engineers have developed several other options to suit different applications:

- Wire mesh: Used in thinner concrete elements like slabs, providing distributed reinforcement.

- Fibers: Steel, glass, or synthetic fibers can be mixed directly into the concrete, improving its tensile strength and crack resistance.

- Prestressed tendons: High-strength steel cables tensioned before or after the concrete sets, inducing compressive stresses that counteract tensile forces under load.

Each type of reinforcement has its own advantages and is chosen based on the specific needs of the project, considering factors such as load requirements, environmental conditions, and construction methods.

The Impact of Reinforced Concrete on Modern Construction

Transforming Architectural Possibilities

The development of reinforced concrete in the late 19th century sparked a revolution in construction. Suddenly, engineers could design:

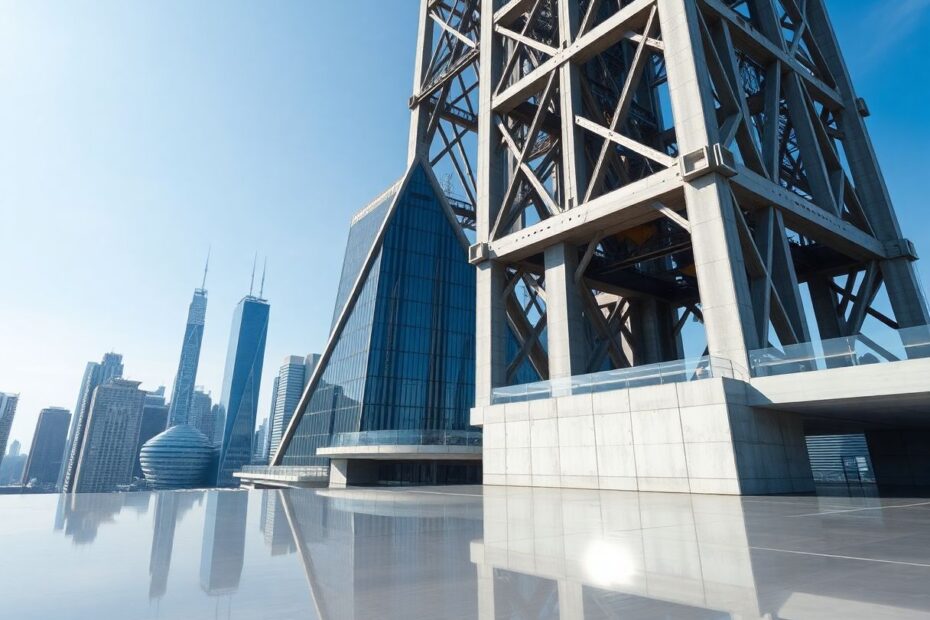

- Taller buildings: Skyscrapers became possible, with reinforced concrete cores providing stability and strength.

- Longer bridges: Spans could stretch further than ever before, connecting communities and facilitating transportation.

- Thinner structures: Concrete shells could create dramatic curved forms, enabling architects to push the boundaries of design.

- More resilient infrastructure: Roads, dams, and tunnels could withstand greater forces and environmental stresses.

Notable Reinforced Concrete Structures

Some iconic examples of reinforced concrete in action include:

- Hoover Dam: This massive structure contains 3.25 million cubic yards of concrete, enough to build a two-lane highway from San Francisco to New York.

- Sydney Opera House: Its distinctive shell-like roof forms are made possible by reinforced concrete, showcasing the material's versatility in creating complex geometries.

- Burj Khalifa: The world's tallest building, standing at 828 meters (2,717 feet), relies on a reinforced concrete core for its stability and strength.

These structures demonstrate the incredible potential of reinforced concrete when combined with innovative engineering and architectural vision.

Advancing the Science: Prestressed Concrete

For even greater strength and span capabilities, engineers developed prestressed concrete. This technique involves:

- Stretching high-strength steel tendons

- Casting concrete around the tensioned tendons

- Once the concrete hardens, releasing the tension

The result is concrete that's permanently in compression, making it even more resistant to cracking under load. This technology has enabled the construction of longer bridge spans, thinner floor slabs in buildings, and more efficient use of materials overall.

Challenges and Innovations in Reinforced Concrete

Addressing the Weaknesses

Despite its many advantages, reinforced concrete faces some significant challenges:

Corrosion: If water and air reach the steel reinforcement, it can rust and expand, cracking the concrete. This is particularly problematic in marine environments or areas where de-icing salts are used.

Alkali-silica reaction: Some aggregates react with cement over time, causing internal swelling and cracking. This "concrete cancer" can significantly reduce the lifespan of structures if not properly addressed.

Freeze-thaw damage: Water trapped in concrete can freeze and expand, causing surface damage. This is a major concern in cold climates and can lead to rapid deterioration if not mitigated.

Carbon footprint: Cement production is a major source of CO2 emissions, accounting for about 8% of global emissions. This environmental impact is a significant concern in the face of climate change.

Cutting-Edge Solutions

Engineers and scientists are constantly working to improve reinforced concrete. Some promising developments include:

Self-healing concrete: Researchers at Delft University in the Netherlands have developed concrete containing bacteria that activate when cracks form, sealing them with limestone. This could significantly reduce maintenance costs and extend the lifespan of structures.

Carbon fiber reinforcement: Fiber-reinforced polymer (FRP) bars, made from materials like carbon fiber, offer a corrosion-resistant alternative to steel. They're stronger and lighter than steel, with some types having a tensile strength up to 5 times higher than traditional rebar.

Geopolymer concrete: This alternative to traditional Portland cement concrete uses industrial byproducts like fly ash or slag to create the binder. It can reduce the carbon footprint of concrete by up to 80% while maintaining comparable strength.

Ultra-high performance concrete (UHPC): This advanced material can achieve compressive strengths over 150 MPa (22,000 psi) and significantly improved durability. Its use allows for thinner, lighter structures and longer lifespans.

The Future of Reinforced Concrete

As we face the challenges of climate change and urbanization, reinforced concrete will continue to play a crucial role in our built environment. The focus is shifting towards:

Sustainability: Reducing the environmental impact of concrete production and use through alternative materials, improved mix designs, and carbon capture technologies.

Durability: Creating structures that last longer with less maintenance, reducing lifecycle costs and resource consumption.

Adaptability: Designing buildings that can be easily modified or recycled, embracing the principles of the circular economy.

Smart materials: Incorporating sensors and reactive elements for better performance and safety. For example, researchers are developing concrete that can conduct electricity to melt ice or self-monitor for damage.

Conclusion: Building on a Strong Foundation

Reinforced concrete has transformed our world, enabling us to build higher, span further, and create more resilient infrastructure than ever before. As we continue to innovate and improve this remarkable material, we're not just mixing cement, water, and steel – we're laying the foundations for the cities and structures of tomorrow.

From the soaring spires of skyscrapers to the sturdy bridges we cross every day, reinforced concrete is the unsung hero of our modern built environment, silently supporting our lives and ambitions. Its story is one of human ingenuity, scientific advancement, and the constant push to overcome limitations.

As we face the challenges of the 21st century, reinforced concrete will undoubtedly continue to evolve, adapting to our changing needs and environmental concerns. With ongoing research into sustainable materials, smart technologies, and innovative design techniques, the future of reinforced concrete looks stronger than ever. The next chapter in its story promises to be one of enhanced durability, reduced environmental impact, and even greater possibilities in shaping our world.

By understanding and appreciating the principles behind reinforced concrete, we gain insight into the complex interplay of science, engineering, and creativity that underpins our built environment. As we look to the future, reinforced concrete will remain a critical tool in addressing global challenges, from providing shelter and infrastructure to mitigating the effects of climate change. The story of reinforced concrete is far from over – in fact, its most exciting and impactful chapters may be yet to come.