Bulletproof glass, a technological marvel that has saved countless lives, has a fascinating history spanning over a century. This article delves into the origins, science, and cutting-edge developments of this crucial safety technology.

The Accidental Birth of an Idea

The story of bulletproof glass begins, like many great inventions, with a fortunate accident. In 1903, French chemist Édouard Bénédictus inadvertently knocked a glass flask from a shelf in his laboratory. To his surprise, while the flask cracked, it didn't shatter into pieces. Upon closer inspection, Bénédictus discovered that the flask had been coated with cellulose nitrate, which had acted as an adhesive, holding the glass fragments together.

This serendipitous event led Bénédictus to develop and patent laminated safety glass in 1909. While not truly "bulletproof," this invention laid the crucial groundwork for the technology we know today.

Early Developments and World War Applications

The concept of laminated glass quickly gained traction, particularly in the automotive industry. By the 1920s, carmakers were using it to reduce injuries from shattered windshields. However, the real push for bulletproof glass came with the onset of World War I and II.

During these conflicts, the military recognized the need for better protection in vehicles and aircraft. This led to significant advancements in glass technology. By the 1930s, the Pittsburgh Plate Glass Company was experimenting with incorporating polyvinyl plastics into laminated glass, a key step towards true bullet resistance.

The Science Behind the Shield

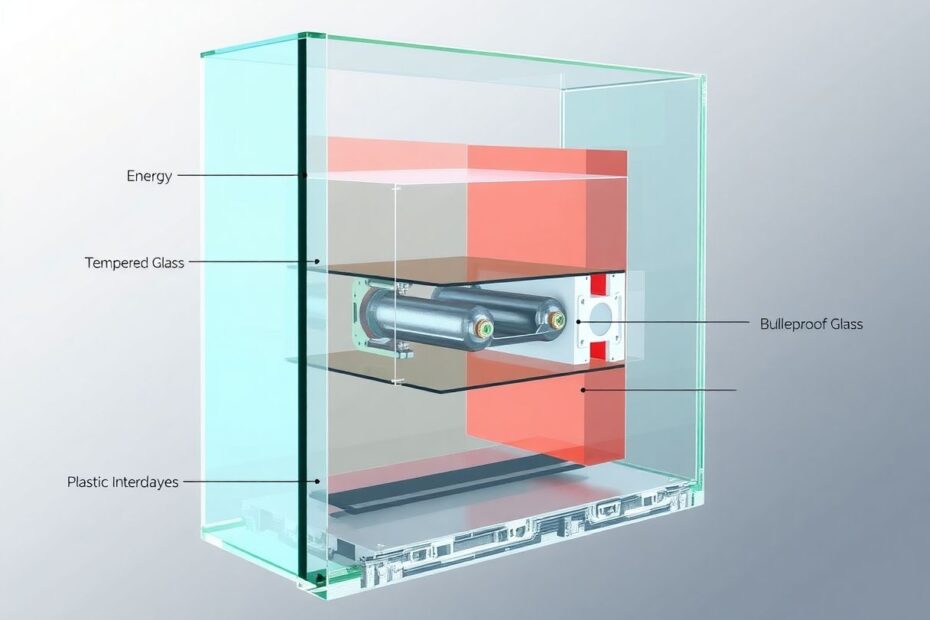

Modern bulletproof glass, more accurately termed "bullet-resistant glass," is a complex laminate composed of alternating layers of glass and plastic. The number and thickness of these layers vary depending on the level of protection required.

The basic principle behind its effectiveness is energy dissipation. When a bullet strikes bulletproof glass:

- The impact energy spreads laterally through the layers.

- Each layer absorbs and dissipates a portion of the energy.

- The bullet decelerates rapidly as it attempts to penetrate.

- By the final layer (if reached), the bullet has lost most of its kinetic energy.

Typically, bulletproof glass consists of:

- Multiple layers of tempered glass (usually 3-10mm thick each)

- Interlayers of various plastics like polyvinyl butyral (PVB), ethylene vinyl acetate, or polycarbonate

- Sometimes, an inner layer of polycarbonate to prevent spalling (the ejection of glass fragments on the protected side)

This multi-layer construction can result in a pane up to ten times thicker than ordinary glass and significantly heavier.

Manufacturing Process: Precision and Control

Creating bulletproof glass is a meticulous process requiring strict quality control. The basic steps include:

- Layering: Carefully stacking alternating layers of glass and plastic.

- Heating: The stack is heated to melt the plastic layers.

- Compression: Applying pressure to bond the layers together.

- Vacuum treatment: Often employed to prevent air bubbles from forming between layers.

- Autoclaving: The final "cooking" process at high temperature and pressure to complete the bonding.

Key challenges in manufacturing include ensuring proper adhesion between layers, preventing air entrapment, and maintaining optical clarity. These factors are crucial for both the protective properties and practical usability of the glass.

Standards and Classifications: Measuring Protection

Bulletproof glass is classified based on its ability to withstand different types of ammunition and impacts. Two primary standards are used globally:

NIJ Standard 0108 (United States):

This standard classifies armor into seven types (I, II-A, II, III-A, III, IV, and Special). Type IV offers the highest protection, capable of stopping a .30 caliber armor-piercing rifle round.BS EN 1063:2000 (United Kingdom and Europe):

This standard provides nine classifications (BR1-BR7 for handguns and rifles, SG1-SG2 for shotguns). BR7 represents the highest level of protection.

These standards help ensure that bulletproof glass meets specific performance criteria for different applications and threat levels.

Applications: From Banks to Battlefields

The versatility of bulletproof glass has led to its adoption across a wide range of sectors:

- Banking: Teller windows and secure areas in financial institutions.

- Government Buildings: Embassies, courthouses, and other high-security facilities.

- Military Vehicles: Armored personnel carriers and other military transports.

- VIP Protection: Limousines for heads of state and other high-profile individuals.

- Law Enforcement: Police vehicles and riot shields.

- Retail: High-risk businesses such as jewelry stores or pawn shops.

- Aerospace: Cockpit windows in some aircraft.

Each application may require different specifications of bulletproof glass, tailored to the specific threats and environmental conditions it may face.

Cutting-Edge Innovations: The Future of Protection

The field of bulletproof glass continues to evolve, with researchers and manufacturers constantly pushing the boundaries of what's possible. Some of the most exciting recent developments include:

Lighter Materials

One of the main challenges with traditional bulletproof glass is its weight. Recent innovations focus on developing lighter materials that offer the same or better protection:

Transparent Aluminum: This exotic material, also known as aluminum oxynitride, is three times stronger than steel but much lighter than traditional bulletproof glass. It's being explored for use in military applications.

Nano-ceramic Composites: By combining nano-scale ceramic particles with polymer matrices, researchers are creating stronger, lighter materials that could revolutionize bulletproof glass.

Self-Healing Glass

The concept of self-healing materials is being applied to bulletproof glass:

- Some experimental glasses can reform their chemical bonds after being shattered, potentially leading to bulletproof glass that "heals" after an impact.

- This technology could significantly extend the lifespan and effectiveness of bulletproof glass in high-risk environments.

Smart Glass Technologies

The integration of electronic components into bulletproof glass is opening new possibilities:

- Electrochromic Glass: This technology allows the glass to change opacity on demand, useful for tactical situations where visibility control is crucial.

- Embedded Sensors: By incorporating sensors into the glass, it's possible to detect and report impacts or attempted breaches, enhancing overall security systems.

Environmental and Ethical Considerations

As with any technology, the production and use of bulletproof glass raise important environmental and ethical questions:

Environmental Impact

- The production of bulletproof glass involves energy-intensive processes, contributing to carbon emissions.

- Disposal of old or damaged bulletproof glass can be challenging due to its composite nature, potentially leading to recycling issues.

Ethical Use

- While primarily designed for protection, there are concerns about the potential misuse of bulletproof glass in fortifying criminal hideouts.

- The proliferation of personal armored vehicles raises questions about escalating arms races in civilian contexts and the potential for increased societal division.

Looking Ahead: The Next Generation of Protection

The future of bulletproof glass is bright and full of potential. Some areas of ongoing research and development include:

Nanotechnology Integration: Incorporating nanomaterials could lead to thinner, stronger glass with enhanced protective properties.

Biomimicry: Drawing inspiration from naturally occurring impact-resistant structures in nature, such as the shells of certain mollusks, to create more effective protective materials.

Multi-functional Materials: Developing glass that's not just bulletproof but also energy-generating or self-cleaning, increasing its utility and value.

Adaptive Structures: Creating glass that can change its properties in response to different threats, potentially offering variable levels of protection as needed.

Conclusion: An Invisible Guardian

From its accidental discovery in a French laboratory to its current state as a critical security technology, bulletproof glass has come a long way. It stands as a testament to human ingenuity in the face of danger, constantly evolving to meet new threats and challenges.

As we look to the future, bulletproof glass will undoubtedly continue to play a crucial role in safety and security across various sectors. Driven by ongoing innovations in materials science and engineering, it promises to become even more effective, versatile, and environmentally friendly.

Whether it's protecting world leaders, safeguarding valuable assets, or keeping law enforcement officers safe in the line of duty, bulletproof glass remains an invisible guardian – a clear barrier between danger and safety. Its story is far from over, and the next chapter in its evolution promises to be as fascinating as its history.

In a world where security threats continue to evolve, bulletproof glass stands as a shining example of how technology can provide peace of mind and save lives. As we continue to push the boundaries of what's possible, we can look forward to even more remarkable developments in this critical field of protective technology.