Nomex, a revolutionary synthetic material, has transformed safety gear and industrial applications since its inception in the 1960s. This comprehensive exploration delves into the composition, properties, and diverse applications of Nomex, unraveling the complex science behind this remarkable material in an accessible manner.

Understanding the Chemical Composition of Nomex

At its core, Nomex is a synthetic aromatic polyamide polymer, classified as an aramid. This scientific terminology encapsulates several key characteristics:

Nomex is entirely laboratory-created, not found in nature. Its molecular structure is based on rings of atoms, giving it the "aromatic" designation. As a polyamide, it consists of multiple amide molecules linked together, forming a large molecule made up of repeating subunits – the definition of a polymer.

The chemical name for Nomex, poly(m-phenylenediamine isophthalamide), provides insight into its molecular structure. This complex arrangement of carbon, hydrogen, oxygen, and nitrogen atoms in a specific pattern is the secret behind Nomex's extraordinary properties.

The Molecular Magic of Nomex

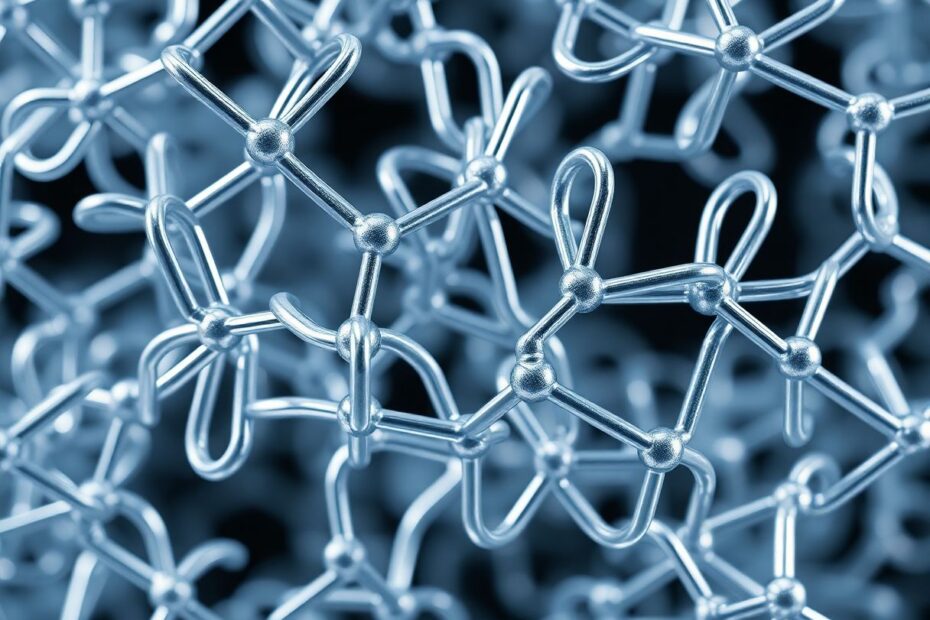

Nomex's structure can be visualized as a string of interconnected paper clips, where each clip represents a monomer unit, and the entire chain forms the polymer. This unique arrangement is crucial to understanding why Nomex performs so exceptionally in extreme conditions.

The production of Nomex involves a two-stage process. First, organic compounds react to form a liquid polymer. This liquid is then carefully spun into solid fibers, which can be woven into fabric or formed into sheets. This meticulous process allows for precise control over the material's properties, ensuring consistency and quality in every batch.

Varieties of Nomex: Tailored for Specific Needs

Nomex isn't a one-size-fits-all material. It comes in several varieties, each designed for specific applications:

Pure Nomex fibers make up the standard 100% Nomex material. For enhanced strength, Nomex can be blended with up to 60% Kevlar, another high-performance aramid fiber. Nomex III, a specialized blend, incorporates Nomex, Kevlar, and anti-static fibers, offering a combination of heat resistance, strength, and electrostatic discharge protection.

The Extraordinary Properties of Nomex

Nomex's most celebrated feature is its exceptional heat and flame resistance. When exposed to flame, Nomex chars but doesn't continue burning once the heat source is removed. This self-extinguishing property is crucial in protective gear. The tightly woven structure of Nomex fibers also acts as a formidable heat barrier, slowing heat transfer and providing vital protection in high-temperature environments.

To put this in perspective, a standard cotton t-shirt typically ignites within 2 seconds and can burn for several minutes. In contrast, Nomex takes about 4 seconds to ignite and extinguishes within 5 seconds of removing the flame source. This difference can be life-saving in emergency situations.

The strength and durability of Nomex fibers are equally impressive. The material's aromatic ring structure and strong inter-polymer bonds distribute forces efficiently, much like a well-designed bridge. This molecular architecture results in a material that is incredibly strong for its weight.

Surprisingly, Nomex is also an excellent electrical insulator. The same tightly packed molecular structure that resists heat also impedes the flow of electrons, making Nomex ideal for use in electrical equipment.

Nomex in Action: Real-World Applications

The unique properties of Nomex make it invaluable across various fields:

In protective clothing, Nomex is a crucial component in firefighting gear, providing essential heat and flame protection. Race car drivers rely on Nomex suits for survival in the event of a fiery crash. Military personnel benefit from Nomex's flame-resistant properties in combat situations, while astronauts incorporate it into their space suits for thermal protection.

Industrial applications of Nomex are equally diverse. Its electrical insulation properties make it ideal for use in motors, generators, and transformers. High-temperature industrial filters often utilize Nomex for its heat resistance and durability. In aerospace, Nomex is used in honeycomb structures, providing lightweight yet strong components for aircraft and spacecraft.

Even in everyday items, Nomex finds its place. Many heat-resistant kitchen gloves and ironing board covers incorporate Nomex, bringing its protective properties into our homes.

Nomex vs. The Competition: A Material Comparison

To truly appreciate Nomex, it's essential to compare it to alternative materials:

Cotton, while comfortable, burns easily and offers minimal heat protection. Wool, though naturally flame-resistant, can't match Nomex's durability or heat resistance. Kevlar, another aramid fiber, surpasses Nomex in strength but falls short in heat resistance. Polyester, a common synthetic fabric, melts at high temperatures, potentially causing severe burns.

Nomex stands out for its unique combination of heat resistance, strength, and durability – a trifecta that's hard to beat in safety applications.

The Science of Flame Resistance: Nomex's Molecular Shield

Nomex's flame resistance isn't a surface treatment or additive; it's an inherent property of the material's molecular structure. When exposed to extreme heat, Nomex fibers undergo a fascinating transformation:

- The fibers absorb energy, causing them to swell and thicken.

- This swelling creates a protective barrier between the heat source and the wearer's skin.

- Unlike materials that melt or disintegrate, the charred Nomex fibers maintain their integrity.

This process is analogous to how trees create charcoal during a forest fire, which can protect the inner layers of wood. In Nomex, this molecular-level response provides crucial moments of protection in life-threatening situations.

Environmental Considerations and Future Developments

While Nomex offers incredible benefits, it's important to consider its environmental impact. As a synthetic material, Nomex is not biodegradable, which raises concerns about its long-term environmental effects. However, its durability means less frequent replacement, potentially reducing overall waste.

Efforts are underway to develop more sustainable production methods and end-of-life solutions for aramid fibers like Nomex. Some recycling programs exist, but they're not yet widely available. As environmental consciousness grows, we can expect to see more research into eco-friendly alternatives and recycling processes for high-performance materials like Nomex.

Looking to the future, Nomex continues to evolve. Researchers are exploring the integration of smart textiles, combining Nomex with sensors for real-time monitoring of temperature and other factors. Enhanced blends with other advanced materials are being developed to push the boundaries of performance even further. Nanotechnology applications are also being investigated to improve Nomex's properties at the molecular level.

The Birth of Nomex: A Triumph of Scientific Innovation

The story of Nomex's invention is a testament to the power of scientific research and innovation. Dr. Wilfred Sweeny at DuPont created Nomex in the 1960s while researching polymers with enhanced thermal properties. Introduced commercially in 1967, Nomex quickly found applications in firefighting and industrial safety, revolutionizing personal protective equipment.

The development of Nomex showcases how fundamental research in chemistry and materials science can lead to practical, life-saving innovations. It's a prime example of how scientific curiosity, combined with rigorous experimentation, can result in products that significantly impact society.

Conclusion: Nomex's Lasting Impact on Safety and Technology

Nomex exemplifies the profound impact that advanced materials science can have on safety and industrial capabilities. From its intricate molecular structure to its wide-ranging applications, Nomex continues to protect lives and enable technological advancements across various sectors.

Understanding the composition and properties of Nomex – from its atomic components to its polymer structure – provides insight into why it performs so exceptionally in extreme conditions. This knowledge not only helps us appreciate the material but also inspires future innovations in material science.

As we look ahead, Nomex and similar advanced materials will continue to evolve, offering even greater protection and enabling new technologies. The ongoing story of Nomex serves as a powerful reminder that with scientific curiosity, persistent research, and innovative thinking, we can create solutions to some of our most challenging problems, making the world a safer and more technologically advanced place.

In conclusion, Nomex stands as a triumph of chemical engineering and a testament to the power of scientific innovation. Its unique composition allows it to stand up to extreme conditions where other materials fail, making it an indispensable part of modern safety equipment and industrial applications. As we continue to push the boundaries of what's possible in materials science, Nomex will undoubtedly play a crucial role in shaping a safer, more resilient future.