Styrofoam, the ubiquitous white foam material we encounter in everyday life, has long been associated with keeping things cold or hot. But what exactly is the science behind its insulating properties? Does Styrofoam actually absorb heat, or is there more to the story? In this comprehensive exploration, we'll unravel the mysteries of Styrofoam's interaction with heat, examine its effectiveness as an insulator, and consider its place in the broader context of insulation technology and environmental sustainability.

Understanding Styrofoam: More Than Just Foam

To truly grasp Styrofoam's role in heat insulation, we must first understand what it is. Styrofoam is actually a trademarked brand name for a specific type of expanded polystyrene foam (EPS) manufactured by the Dow Chemical Company. However, the term has become genericized, much like "Kleenex" for tissues, and is often used to refer to any similar foam product.

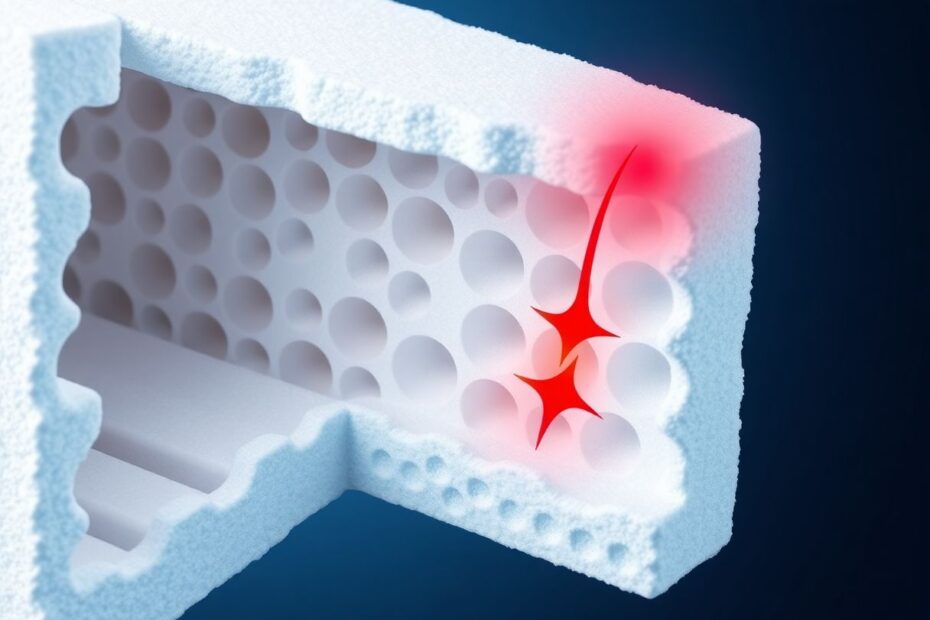

At its core, Styrofoam is a marvel of materials science. It's created through a process called expansion, where polystyrene beads are exposed to steam, causing them to expand up to 40 times their original size. The result is a material composed of approximately 98% air and only 2% plastic. This unique composition is key to understanding its insulating properties.

The cellular structure of Styrofoam is what gives it its remarkable characteristics. Each cubic inch contains millions of tiny air pockets, creating a labyrinth that significantly impedes heat transfer. This structure is not random but carefully engineered to maximize insulation while minimizing material use.

The Physics of Heat Transfer: Styrofoam's Battleground

To appreciate how Styrofoam functions as an insulator, we need to delve into the physics of heat transfer. Heat, in essence, is energy in transit, always moving from warmer areas to cooler ones. This transfer occurs through three primary mechanisms:

- Conduction: The direct transfer of thermal energy through a material at the molecular level.

- Convection: Heat transfer through the movement of fluids or gases.

- Radiation: The emission of electromagnetic waves that carry energy away from the source.

Styrofoam's effectiveness lies in its ability to combat all three of these mechanisms simultaneously. Let's break down how it tackles each one:

Conduction: The Plastic Barrier

Styrofoam's plastic component, polystyrene, has inherently low thermal conductivity. This means that heat struggles to move directly through the material. The thermal conductivity of Styrofoam typically ranges from 0.033 to 0.040 W/(m·K), which is significantly lower than many common materials. For comparison, copper, an excellent conductor, has a thermal conductivity of about 385 W/(m·K) – nearly 10,000 times higher!

Convection: Trapped Air as Insulation

The real magic of Styrofoam's insulating power comes from its structure. Those millions of tiny air pockets severely restrict air movement within the material. Since air is an excellent insulator when it's not moving, this dramatically reduces heat transfer via convection. It's worth noting that the air in these pockets isn't ordinary air – it's often a mixture of air and the blowing agent used in the manufacturing process, which can have even lower thermal conductivity than standard air.

Radiation: Reflection Over Absorption

When it comes to radiant heat, Styrofoam's white color plays a crucial role. White surfaces reflect more radiant energy than they absorb, helping to bounce back infrared radiation rather than allowing it to penetrate the material. This property is particularly useful in applications where radiant heat is a significant factor, such as in building insulation.

The Myth of Heat Absorption

Now, let's address the central question: Does Styrofoam absorb heat? The short answer is no, at least not in the way many people might think. Styrofoam doesn't actively absorb or "suck up" heat like a sponge absorbs water. Instead, it acts as a barrier, slowing down the transfer of heat from one side of the material to the other.

This misconception likely arises from the fact that Styrofoam can feel warm to the touch when it's been in contact with a hot object. However, this warmth is simply the result of the surface of the Styrofoam reaching thermal equilibrium with its surroundings – the bulk of the material remains an effective insulator.

Quantifying Insulation: R-Value and Beyond

In the world of insulation, effectiveness is often measured using R-value. This metric quantifies a material's thermal resistance – its ability to resist heat flow. The higher the R-value, the better the insulation. Styrofoam typically boasts an R-value of around 5 per inch of thickness, which is quite impressive.

To put this in perspective, let's compare Styrofoam to some other common insulation materials:

- Fiberglass: R-2.2 to R-2.7 per inch

- Cellulose: R-3.1 to R-3.8 per inch

- Polyurethane Foam: R-6.3 per inch

- Aerogel: Up to R-14 per inch

While Styrofoam isn't the highest performer on this list, its combination of good insulation, light weight, and relatively low cost makes it a popular choice for many applications.

It's important to note that R-value alone doesn't tell the whole story. Factors like moisture resistance, durability, and ease of installation also play crucial roles in real-world insulation performance. Styrofoam excels in many of these areas, particularly in its resistance to moisture, which can significantly degrade the performance of some other insulation materials over time.

Styrofoam in Action: Real-World Applications

The unique properties of Styrofoam have led to its use in a wide array of applications, many of which leverage its insulating capabilities:

Construction: Styrofoam is commonly used in building insulation, particularly in the form of rigid foam boards. These can be applied to walls, roofs, and foundations to improve a structure's overall energy efficiency.

Cold Chain Logistics: The food and pharmaceutical industries rely heavily on Styrofoam for shipping temperature-sensitive products. Its insulating properties help maintain consistent temperatures during transport.

Buoyancy Devices: The combination of low density and water resistance makes Styrofoam ideal for use in life jackets and other flotation devices.

Disposable Containers: Although becoming less common due to environmental concerns, Styrofoam cups and food containers have been popular due to their ability to keep hot foods hot and cold foods cold.

Horticultural Applications: Styrofoam is sometimes used in hydroponic systems and as a soil amendment to improve drainage and aeration while providing some insulation to plant roots.

The Environmental Conundrum

While Styrofoam's insulating properties are impressive, its environmental impact has become a significant concern in recent years. The material's resistance to degradation, which makes it so effective as an insulator, also means that it persists in the environment for hundreds of years. Moreover, the production of Styrofoam involves the use of hydrofluorocarbons (HFCs), which are potent greenhouse gases.

Recycling Styrofoam presents another challenge. While technically recyclable, many recycling facilities don't accept it due to the costs and complexities involved in processing. This has led to large amounts of Styrofoam ending up in landfills or, worse, in natural environments where it can harm wildlife.

These environmental concerns have spurred research into more sustainable alternatives and improved recycling methods. Some promising developments include:

- Biodegradable Foam Alternatives: Materials made from cornstarch, mushroom mycelium, or other organic substances that can decompose naturally.

- Advanced Recycling Technologies: New methods for breaking down Styrofoam into its base components for reuse.

- Circular Economy Initiatives: Programs that collect and repurpose used Styrofoam, extending its lifecycle.

The Future of Insulation Technology

As we look to the future, the field of insulation technology is ripe with innovation. While Styrofoam has set a high bar for performance and cost-effectiveness, new materials and techniques are emerging that could revolutionize how we think about heat insulation:

Aerogels: Often called "frozen smoke," aerogels are incredibly light, porous materials with exceptional insulating properties. While currently expensive, ongoing research is bringing them closer to commercial viability for widespread use.

Vacuum Insulated Panels (VIPs): These panels achieve extremely high R-values by removing air altogether, creating a vacuum between two layers of thin, gas-impermeable film.

Phase Change Materials (PCMs): These substances absorb or release heat as they change from solid to liquid and back, helping to regulate temperatures in buildings.

Nanotechnology: Manipulating materials at the nanoscale opens up new possibilities for creating insulators with unprecedented performance.

Biomimetic Insulation: Inspired by nature, researchers are developing materials that mimic the insulating properties of polar bear fur or penguin feathers.

Conclusion: Styrofoam in the Bigger Picture of Heat Insulation

As we've explored, Styrofoam's relationship with heat is more complex than simple absorption. Its effectiveness as an insulator stems from its unique structure and composition, which work together to impede heat transfer through conduction, convection, and radiation.

While Styrofoam has been a game-changer in many industries due to its insulating properties, we must also grapple with its environmental impact. The challenge moving forward will be to develop materials and technologies that can match or exceed Styrofoam's insulating performance while addressing sustainability concerns.

For now, Styrofoam remains an important player in the world of insulation, and understanding its properties can help us make informed decisions about its use. Whether in construction, packaging, or any of its myriad applications, Styrofoam continues to play a crucial role in managing heat transfer in our daily lives.

As we continue to push the boundaries of materials science and engineering, the future of heat insulation looks promising. From aerogels to biomimetic materials, new technologies are emerging that could reshape our approach to energy efficiency and thermal management. In this evolving landscape, the principles we've learned from Styrofoam – the importance of structure, air entrapment, and material properties in insulation – will undoubtedly continue to inform and inspire the next generation of insulation solutions.