Imagine being able to lift a car with just one hand, or effortlessly hoist a piano to the top floor of a skyscraper. While these feats might sound like something out of a superhero movie, they're actually possible thanks to one of humanity's oldest and most ingenious inventions: the pulley. These simple machines have been revolutionizing the way we work with heavy loads for thousands of years, and their impact on our world cannot be overstated.

In this comprehensive exploration of pulleys, we'll uncover the fascinating physics behind their operation, delve into their various types and applications, and even peek into the future of this timeless technology. Whether you're a budding engineer, a DIY enthusiast, or simply curious about the world around you, understanding pulleys offers a window into the elegant solutions that physics provides to everyday challenges.

The Fundamentals: What Exactly is a Pulley?

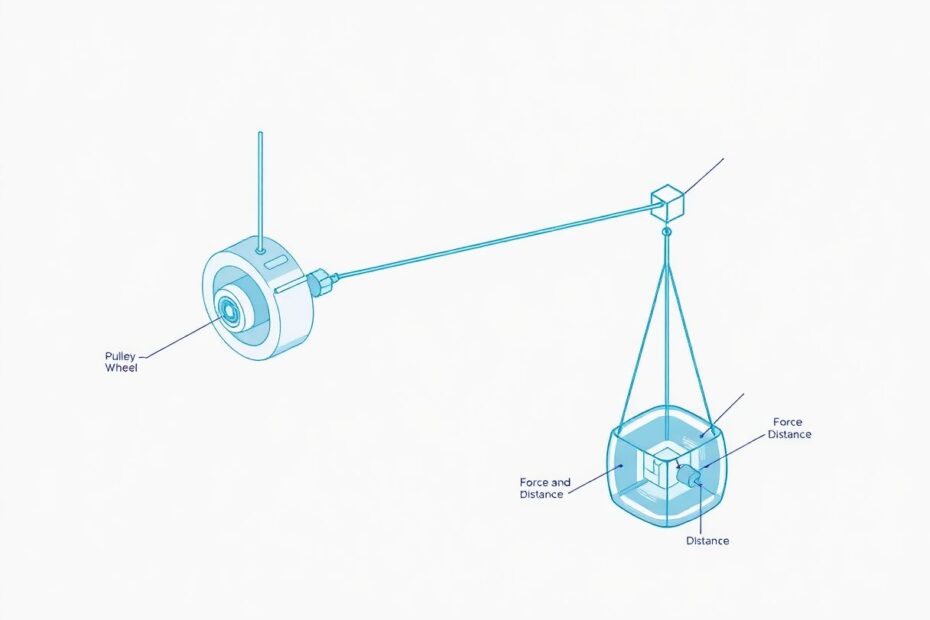

At its core, a pulley is disarmingly simple: it's a wheel with a grooved rim around which a rope or cable can run. This basic setup allows us to change the direction of an applied force and, in certain configurations, provides a mechanical advantage that multiplies our strength. But don't let this simplicity fool you – the implications of this design are profound and far-reaching.

To truly grasp how pulleys work, we need to understand a few key physical concepts:

Force: This is the push or pull exerted on an object. In the context of pulleys, it's typically the effort we apply to lift or move a load.

Work: Defined as the product of force and distance (Work = Force × Distance), this concept is crucial to understanding why pulleys don't actually reduce the total effort required to move an object.

Mechanical Advantage: This is the factor by which a machine multiplies the force applied to it. It's one of the primary benefits of using pulley systems.

The fundamental principle underlying all pulley systems is the conservation of energy. While pulleys can make lifting feel easier, they don't actually reduce the amount of work required to lift an object. Instead, they offer a trade-off between force and distance.

The Physics Behind the Power: How Pulleys Multiply Force

Let's break down the mechanics of a simple movable pulley system to illustrate this principle:

Imagine you have a 100kg weight you want to lift. You attach a movable pulley to the weight, with one end of the rope fixed to a beam above. The rope runs through the movable pulley and then back up to your hands. When you pull on the free end of the rope, the weight is supported by two sections of rope, each effectively bearing half the weight. This means you only need to exert 50kg of force to lift the 100kg weight.

However, there's a catch: while you're only pulling with half the force, you need to pull twice the distance. If you want to lift the weight 1 meter, you'll need to pull 2 meters of rope. This relationship is described by the equation:

Force × Distance = Weight × Height

This equation encapsulates a fundamental truth about pulleys and indeed all simple machines: they don't change the total amount of work done, but they allow us to apply that work in ways that are more convenient or manageable for human strength.

Types of Pulley Systems: From Simple to Complex

Pulleys come in various configurations, each with its own advantages and applications:

Fixed Pulley: This type doesn't move; it's attached to a stable surface. While it changes the direction of the force, it doesn't provide any mechanical advantage. You still need to exert the same amount of force as the weight of the object you're lifting. Think of a flag being raised on a flagpole – the pulley at the top allows you to pull down to lift the flag up, but you're still lifting the full weight of the flag.

Movable Pulley: This type is attached to the load and moves with it. It provides a mechanical advantage of 2, meaning you only need to exert half the force to lift the load. Picture a heavy crate being lifted with the pulley attached to the crate itself.

Compound Pulley (Block and Tackle): This system combines fixed and movable pulleys to provide significant mechanical advantage. Large cranes use compound pulley systems to lift enormous weights. The more wheels and ropes in the system, the greater the mechanical advantage.

The mechanical advantage (MA) of a pulley system is determined by the number of rope sections supporting the weight. For a single fixed pulley, MA = 1. For a single movable pulley, MA = 2. In a compound system, the MA equals the number of rope sections supporting the weight. This can be expressed mathematically as:

Mechanical Advantage = Number of rope sections supporting the weight

Real-World Applications: Pulleys in Action

Pulleys are ubiquitous, playing crucial roles in numerous fields:

Construction: Cranes use complex pulley systems to lift heavy materials, enabling the construction of skyscrapers and other large structures.

Fitness Equipment: Many gym machines, like cable machines and rowing machines, use pulleys to provide adjustable resistance.

Elevators: Modern elevators employ multiple pulleys and counterweights to safely and efficiently transport people and goods vertically.

Sailing: On sailboats, pulleys (called blocks in nautical terms) control sails and rigging, allowing small crews to manage large sails.

Theater: Stage curtains, lighting rigs, and set pieces are often controlled by sophisticated pulley systems.

Industrial Manufacturing: Factories use pulleys in conveyor systems and for moving heavy equipment.

Automotive: Car engines use a type of pulley system in their belt drives to power various components.

The Efficiency Factor: Overcoming Friction

In an ideal world, pulleys would be 100% efficient, perfectly translating input force to output force. However, in reality, friction between the rope and the pulley wheel, as well as within the pulley's axle, reduces efficiency. This means you need to exert slightly more force than the theoretical minimum to overcome this friction.

Modern engineering has made significant strides in minimizing these losses. High-quality pulleys use precision bearings and specialized materials to reduce friction. For example, some advanced pulleys use ceramic bearings which can reduce friction by up to 30% compared to standard steel bearings. Synthetic ropes made from materials like Dyneema or Spectra not only reduce weight but also minimize rope-pulley friction.

Despite these advancements, some energy loss is inevitable. In practical applications, pulley system efficiency typically ranges from 70% to 95%, depending on the quality of components and the complexity of the system.

Pulleys Through Time: A Brief History

The use of pulleys dates back to ancient times, with evidence of their use in Mesopotamia as early as 1500 BCE. The Greek mathematician Archimedes is credited with inventing the compound pulley system around 250 BCE, significantly advancing the technology.

Throughout history, pulleys have played pivotal roles in human achievement:

- Ancient Egyptians likely used pulleys in the construction of the pyramids, although the exact methods are still debated.

- During the Age of Sail (16th to 19th centuries), complex pulley systems were essential for managing the rigging of large ships.

- The Industrial Revolution saw pulleys integrated into a wide array of machinery, powering factories and enabling mass production.

- In modern times, pulleys have been crucial in the construction of skyscrapers, the operation of space launch systems, and even in the development of nanotechnology.

Beyond Lifting: Other Applications of Pulley Principles

While we often associate pulleys with lifting heavy objects, the principles behind them have broader applications:

Timing Belts: Many engines use a toothed belt running over pulleys to synchronize the rotation of the crankshaft and camshaft.

Belt Drives: Used in many machines to transfer power from one rotating shaft to another.

Cable Exercise Machines: These use pulleys to create smooth, variable resistance for strength training.

Clotheslines: A simple application of the fixed pulley principle for hanging laundry.

Shower Curtains: The rings that allow a shower curtain to slide easily are a form of pulley.

Bicycle Gears: While not pulleys in the traditional sense, bike gears apply similar principles to modify force and speed.

The Future of Pulleys: Innovations on the Horizon

While the basic principle of pulleys remains unchanged, modern materials and designs continue to improve their efficiency and capabilities. Some exciting developments include:

Synthetic Ropes: New materials like ultra-high-molecular-weight polyethylene (UHMWPE) create ropes that are stronger and lighter than steel cables, allowing for higher lift capacities with less weight.

Smart Pulleys: Integration of sensors and IoT technology allows for real-time monitoring of load, wear, and efficiency in industrial applications.

3D-Printed Pulleys: Additive manufacturing enables the creation of custom-designed pulleys with optimized geometries for specific applications.

Nanoscale Pulleys: At the molecular level, scientists are developing "molecular pulleys" for use in nanotechnology and advanced materials.

Magnetic Pulleys: For certain applications, magnetic levitation could reduce friction even further than traditional bearings.

DIY Pulley Experiments: Hands-On Learning

Understanding pulleys becomes much easier with practical experience. Here are some experiments you can try at home:

Single Fixed Pulley:

Materials: A sturdy rod, a pulley wheel, rope, and a small weight.

Setup: Mount the pulley on the rod, run the rope over it, and attach the weight.

Experiment: Feel the difference between lifting the weight directly and using the pulley.Single Movable Pulley:

Materials: Same as above, plus a hook to fix one end of the rope.

Setup: Attach one end of the rope to the hook, run it through the pulley attached to the weight, then back up.

Experiment: Compare the force needed to lift the weight with this setup versus the fixed pulley.Compound Pulley:

Materials: Multiple pulleys, rope, weight, and mounting points.

Setup: Create a system with several pulleys, some fixed and some movable.

Experiment: Observe how increasing the number of pulleys affects the force required and the distance the rope must be pulled.

These experiments can provide a tangible understanding of mechanical advantage and the force-distance trade-off inherent in pulley systems.

Safety and Maintenance: Ensuring Longevity and Reliability

While pulleys make lifting easier, they can be dangerous if not used properly. Key safety considerations include:

- Always check the weight rating of your pulley system and never exceed it.

- Inspect ropes and cables regularly for wear or damage.

- Ensure all mounting points are secure before lifting.

- Keep hands and loose clothing away from moving parts.

- Never stand under a lifted load.

Proper maintenance is crucial for the longevity and reliability of pulley systems:

- Lubricate moving parts regularly, using appropriate lubricants for the specific application.

- Replace worn ropes or cables promptly to prevent sudden failure.

- Clean pulleys to prevent debris buildup, which can increase friction and wear.

- Store equipment properly when not in use to prevent environmental damage.

Conclusion: The Enduring Power of Pulleys

As we've explored, pulleys are far more than simple wheels with grooves. They represent a fundamental understanding of physics, a brilliant application of mechanical principles that has stood the test of time. From the ancient wonders of the world to the marvels of modern engineering, pulleys have been there, quietly multiplying our strength and expanding our capabilities.

The next time you see a crane lifting a massive steel beam, adjust the resistance on a gym machine, or even raise a flag, take a moment to appreciate the simple yet profound science at work. Pulleys may be ancient technology, but they continue to shape our world in remarkable ways, embodying the timeless principles of physics that govern our universe.

Whether you're a student of engineering, a DIY enthusiast, or simply curious about the mechanics of the world around you, understanding pulleys offers invaluable insights into the power of simple machines and the ingenuity of human problem-solving. So go ahead, experiment with pulleys, and experience for yourself the amazing feeling of lifting far more than you thought possible – all thanks to a wheel, a rope, and the clever application of scientific principles that have been empowering human achievement for millennia.