In the ever-evolving world of 3D printing, two technologies stand out for their popularity and versatility: resin-based and PLA-based 3D printing. As a tech enthusiast diving into this fascinating realm, understanding the nuances between these two methods is crucial for choosing the right approach for your projects. This comprehensive guide will explore the intricacies of both technologies, helping you make an informed decision and elevate your 3D printing game.

The Foundations of 3D Printing

Before we delve into the specifics of resin and PLA printing, it's essential to understand the basics of 3D printing technology. At its core, 3D printing is an additive manufacturing process that creates three-dimensional objects from digital files. The printer interprets the design and constructs the object layer by layer, resulting in a physical item with volume, texture, and structural integrity.

Resin 3D Printing: Precision in Liquid Form

The Science Behind Resin Printing

Resin 3D printing, also known as stereolithography (SLA) or Digital Light Processing (DLP), utilizes a photosensitive liquid resin that solidifies when exposed to UV light. This process offers unparalleled precision and detail, making it a favorite among hobbyists and professionals alike for creating intricate models and prototypes.

The printing process begins with a build platform lowered into a vat of liquid resin. A UV laser or LED screen then precisely cures specific areas of the resin, solidifying it layer by layer. As each layer is completed, the platform rises slightly, and the process repeats until the entire object is formed. After printing, the object requires washing to remove excess resin and post-curing to achieve optimal strength and stability.

Advantages of Resin Printing

Resin printing boasts several significant advantages that make it attractive for certain applications. Perhaps the most notable is its exceptional detail capability. Resin printers can achieve layer heights as low as 25 microns, resulting in incredibly smooth surfaces and fine details that are often indistinguishable from injection-molded parts.

Another advantage is the isotropic strength of resin prints. Unlike FDM prints, which can have weak points between layers, resin prints exhibit consistent strength in all directions due to the chemical bonding that occurs during the curing process. This makes resin prints ideal for applications requiring structural integrity and uniform mechanical properties.

Resin printing also offers a wide variety of specialized materials. From flexible resins that mimic rubber to castable resins for jewelry making, and even biocompatible resins for dental applications, the versatility of resin printing extends far beyond standard plastics.

Challenges and Considerations

While resin printing offers many benefits, it's not without its challenges. Safety is a primary concern when working with liquid resins. These materials are toxic before curing and require careful handling, proper ventilation, and protective equipment. This aspect of resin printing can be daunting for beginners or those without a dedicated workspace.

Post-processing is another consideration. Resin prints require washing in isopropyl alcohol or specialized cleaning solutions to remove uncured resin, followed by post-curing under UV light to achieve full strength. This adds extra steps and time to the printing process compared to FDM methods.

Cost is also a factor to consider. Both resin printers and the materials tend to be more expensive than their FDM counterparts. While prices have decreased in recent years, resin printing still represents a higher initial investment and ongoing material costs.

Lastly, most consumer-grade resin printers have smaller build volumes compared to FDM printers. This can limit the size of objects you can print in a single piece, potentially requiring more complex assembly for larger projects.

PLA 3D Printing: The Versatile Filament Option

Understanding PLA Printing Technology

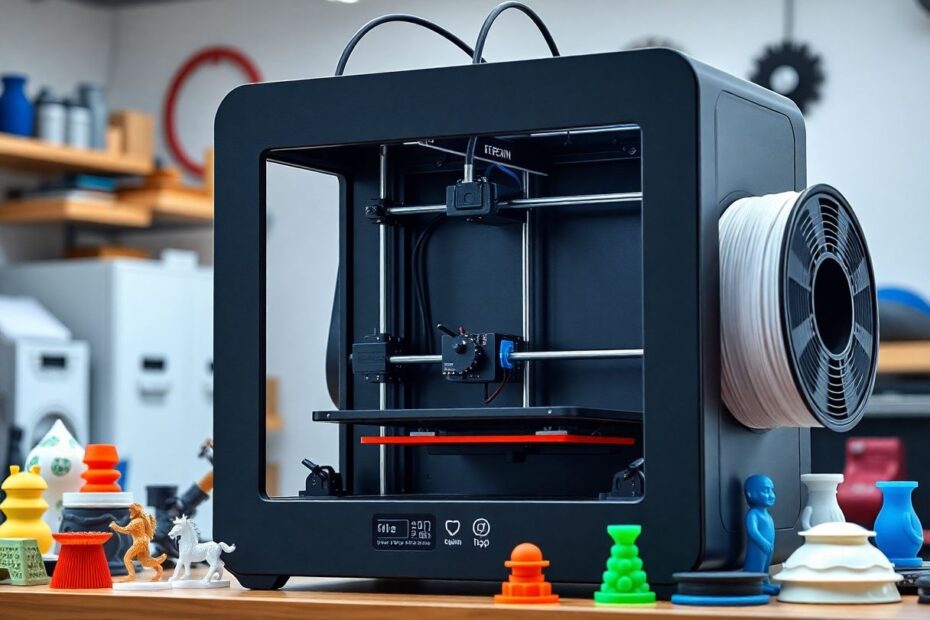

PLA (Polylactic Acid) printing falls under the category of Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). This method has become incredibly popular due to its accessibility and ease of use, making it an excellent entry point for 3D printing enthusiasts.

In PLA printing, a spool of filament is fed into a heated nozzle, where it melts and is extruded onto a build plate. The printer moves in three dimensions, depositing the molten plastic layer by layer to build the object. As each layer cools, it solidifies, bonding with the previous layers to create a solid structure.

Benefits of PLA Printing

PLA printing offers several advantages that have contributed to its widespread adoption. First and foremost is its user-friendliness. PLA is easier to work with than many other materials, with a lower melting point and minimal warping, making it ideal for beginners. It doesn't require a heated build plate, simplifying the printing process and reducing equipment costs.

Affordability is another significant benefit of PLA printing. Both PLA filament and FDM printers are generally less expensive than their resin counterparts, lowering the barrier to entry for 3D printing. This accessibility has fostered a large and supportive community of makers and enthusiasts, resulting in a wealth of resources and shared knowledge.

PLA is also noted for its environmental friendliness. Derived from renewable resources such as corn starch or sugarcane, PLA is biodegradable under the right conditions. This aligns well with the growing focus on sustainability in technology and manufacturing.

Another advantage of PLA is its low odor during printing. Unlike some other filaments that can produce strong fumes, PLA is relatively pleasant to work with, making it suitable for home use without extensive ventilation requirements.

Limitations and Considerations

While PLA printing excels in many areas, it's important to understand its limitations. One of the primary drawbacks is the lower detail capability compared to resin printing. FDM prints typically have visible layer lines, which can detract from the smoothness and fine details of the printed object. While post-processing techniques like sanding and painting can mitigate this, achieving the level of detail possible with resin printing remains challenging.

Temperature sensitivity is another consideration with PLA. While its low melting point makes it easy to print, it also means that PLA objects can deform in high-temperature environments. This limits its use in certain applications where heat resistance is required.

The mechanical properties of PLA, while adequate for many applications, may not be suitable for all uses. It's generally less strong and durable than some other 3D printing materials, particularly when subjected to stress or impact.

Comparing Resin and PLA: Key Factors for Tech Enthusiasts

As a tech enthusiast, your choice between resin and PLA printing will likely depend on several factors, including the types of projects you're interested in, your workspace constraints, and your comfort level with the technology.

Print Quality and Detail

When it comes to print quality, resin printing has a clear advantage. The ability to produce layers as thin as 25 microns results in exceptionally smooth surfaces and fine details. This makes resin printing ideal for projects that require high precision, such as miniature figurines for tabletop gaming, intricate jewelry designs, or detailed architectural models.

PLA printing, while capable of good quality, typically produces visible layer lines. The standard layer height for PLA prints ranges from 100 to 200 microns, resulting in a more noticeable stepped appearance on curved surfaces. However, for many functional parts and larger objects, this level of detail is often sufficient.

Ease of Use and Learning Curve

For those new to 3D printing, PLA offers a gentler introduction to the technology. The printing process is straightforward, with fewer variables to manage compared to resin printing. PLA is also more forgiving when it comes to print settings, making it easier to achieve successful prints even as a beginner.

Resin printing, while not overly complex, does involve more steps and considerations. The need for proper safety precautions, precise resin handling, and post-processing can be intimidating for newcomers. However, for tech enthusiasts who enjoy diving deep into a technology, the learning curve of resin printing can be an engaging challenge.

Cost Considerations

When it comes to cost, PLA printing generally has the advantage. Entry-level FDM printers capable of good quality PLA prints are available for under $200, with many excellent options in the $200-$500 range. Resin printers, while becoming more affordable, typically start at a higher price point, often $300 or more for a quality machine.

Material costs also favor PLA, with filament being less expensive per volume than resin. This can be a significant factor for those who plan to print frequently or produce larger objects.

Durability and Functionality

While PLA can produce functional parts, resin prints often exhibit superior strength and durability. The isotropic nature of resin prints means they're less likely to fail along layer lines, a common issue with FDM prints under stress.

Specialized resins can offer properties like flexibility, heat resistance, or impact resistance that surpass standard PLA capabilities. This makes resin printing more versatile for producing end-use parts or prototypes that need to mimic the properties of injection-molded plastics.

Environmental Impact and Safety

From an environmental perspective, PLA has an edge. Its biodegradability and derivation from renewable resources align well with eco-conscious makers. PLA printing also produces minimal fumes, making it safer for home use without extensive ventilation.

Resin printing, on the other hand, requires more careful consideration of environmental impact. Liquid resin is toxic before curing and requires proper disposal of waste products. The need for cleaning solutions and protective equipment also adds to the overall environmental footprint of resin printing.

Practical Applications: Where Each Technology Shines

Understanding where each technology excels can help you choose the right method for your projects.

Resin Printing Sweet Spots

Resin printing is particularly well-suited for:

- Miniature Gaming: The high detail of resin prints makes them perfect for creating intricate tabletop gaming figurines and terrain pieces.

- Jewelry Making: Castable resins allow for the creation of complex jewelry designs that can be used in lost-wax casting processes.

- Dental and Medical Applications: Biocompatible resins enable the production of custom dental aligners, surgical guides, and anatomical models for medical training.

- High-Fidelity Prototyping: When surface finish and fine details are crucial, resin printing offers results that closely mimic injection-molded parts.

PLA Printing Strengths

PLA printing excels in:

- Functional Prototypes: Quick and affordable for testing form and fit of mechanical parts.

- Educational Projects: Safe and easy for classroom or home learning environments, perfect for introducing students to 3D printing technology.

- Cosplay and Props: Large build volumes are ideal for creating costume pieces and movie props.

- Home Decor: From custom planters to decorative items, PLA's variety of colors and finishes makes it great for creating unique home accessories.

The Tech Enthusiast's Perspective

As a tech enthusiast, your approach to 3D printing might differ from casual users or professional applications. Here are some considerations that might resonate with your interests:

Tinkering and Modification Potential

If you enjoy tinkering with hardware, FDM printers often offer more opportunities for modifications and upgrades. From swapping out nozzles to installing direct drive extruders or even converting to a dual extrusion setup, FDM printers provide a playground for hardware enthusiasts.

Resin printers, while less modifiable in terms of hardware, offer extensive opportunities for experimentation with different resin formulations and print parameters. This can be particularly appealing if you're interested in materials science or pushing the boundaries of print quality.

Software Exploration

Both technologies benefit from a rich ecosystem of slicing software and CAD tools. However, resin printing often requires more advanced settings and support structures, providing an opportunity to dive deep into the intricacies of 3D model preparation and print optimization.

For those interested in programming and automation, both FDM and resin printers can be integrated into custom workflows. Whether it's scripting auto-start routines, developing custom calibration procedures, or even integrating your printer with IoT devices, there's ample room for software projects in both realms.

Community and Open Source

The 3D printing community is vast and supportive for both technologies, but you may find more beginner-friendly resources for PLA printing. However, the resin printing community, while smaller, often delves into more advanced topics and cutting-edge applications.

For open-source enthusiasts, there are projects like the RepRap initiative in the FDM world, which aims to create self-replicating 3D printers. In the resin space, projects like NanoDLP provide open-source alternatives to proprietary printer control software.

Expanding Your Skill Set

Regardless of which technology you start with, learning one often provides transferable skills for the other. Understanding 3D modeling, slicing techniques, and the principles of additive manufacturing will serve you well across both platforms.

Many tech enthusiasts find that incorporating both technologies into their toolkit provides the most flexibility. Starting with PLA for its ease of use and then expanding into resin printing for more detailed work is a common progression.

Conclusion: Embracing the 3D Printing Revolution

As we've explored, both resin and PLA 3D printing have their strengths and challenges. Your choice between the two will depend on your specific needs, interests, and the types of projects you want to pursue.

If you're just starting your 3D printing journey, PLA printing offers an accessible entry point with a gentler learning curve and lower initial costs. It's excellent for functional prototypes, larger objects, and projects where material variety and eco-friendliness are priorities.

For those seeking the highest level of detail, or working on projects that require specific material properties, resin printing provides unparalleled precision and a wide range of specialized materials. While it comes with additional considerations in terms of safety and post-processing, the results can be truly impressive.

As a tech enthusiast, you're in an exciting position to explore and push the boundaries of both technologies. Whether you're crafting intricate miniatures with resin or building functional prototypes with PLA, you're part of a community that's reshaping how we think about manufacturing and creativity.

Remember, the world of 3D printing is constantly evolving, with new materials, techniques, and applications emerging regularly. By understanding the fundamentals of resin and PLA printing, you're well-equipped to adapt to future innovations and push the boundaries of what's possible in your own projects.

Embrace the learning process, share your experiences with the community, and most importantly, enjoy the satisfaction of bringing your digital designs into the physical world. Whether you choose resin, PLA, or eventually both, you're embarking on a journey of creativity and innovation that exemplifies the spirit of modern tech enthusiasm.